Decoding The 410A Mini Break up Stress Chart: A Complete Information

Decoding the 410A Mini Break up Stress Chart: A Complete Information

Associated Articles: Decoding the 410A Mini Break up Stress Chart: A Complete Information

Introduction

On this auspicious event, we’re delighted to delve into the intriguing subject associated to Decoding the 410A Mini Break up Stress Chart: A Complete Information. Let’s weave attention-grabbing data and supply recent views to the readers.

Desk of Content material

Decoding the 410A Mini Break up Stress Chart: A Complete Information

Mini-split air con programs, recognized for his or her effectivity and zoning capabilities, rely closely on the refrigerant R-410A. Understanding the pressure-temperature relationship of this refrigerant is essential for correct system prognosis, upkeep, and restore. This text delves deep into the 410A mini-split stress chart, explaining its interpretation, frequent purposes, and the essential function it performs in making certain optimum system efficiency.

Understanding the Fundamentals: Stress, Temperature, and Refrigerant

Earlier than diving into the intricacies of the stress chart, let’s set up the basic relationship between stress, temperature, and refrigerant in a mini-split system. R-410A, a hydrofluoroolefin (HFO) mix, operates underneath considerably larger pressures than its predecessor, R-22. This larger stress is a direct consequence of its completely different thermodynamic properties. The stress throughout the system is immediately correlated to the temperature of the refrigerant at a given level within the refrigeration cycle. The next temperature interprets to larger stress, and vice-versa.

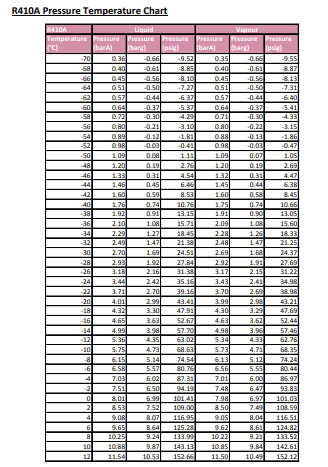

The 410A stress chart visually represents this relationship. It sometimes shows stress (in PSI or kPa) on the vertical axis and temperature (in °F or °C) on the horizontal axis. The chart options two distinct curves: one for the high-pressure aspect (discharge or liquid line) and one for the low-pressure aspect (suction or vapor line). These curves characterize the saturation stress – the stress at which the refrigerant modifications part (from liquid to vapor or vice-versa) at a given temperature.

Decoding the 410A Mini Break up Stress Chart

The chart’s major perform is to permit technicians to find out the refrigerant temperature primarily based on the measured stress, or vice-versa. That is essential for a number of causes:

-

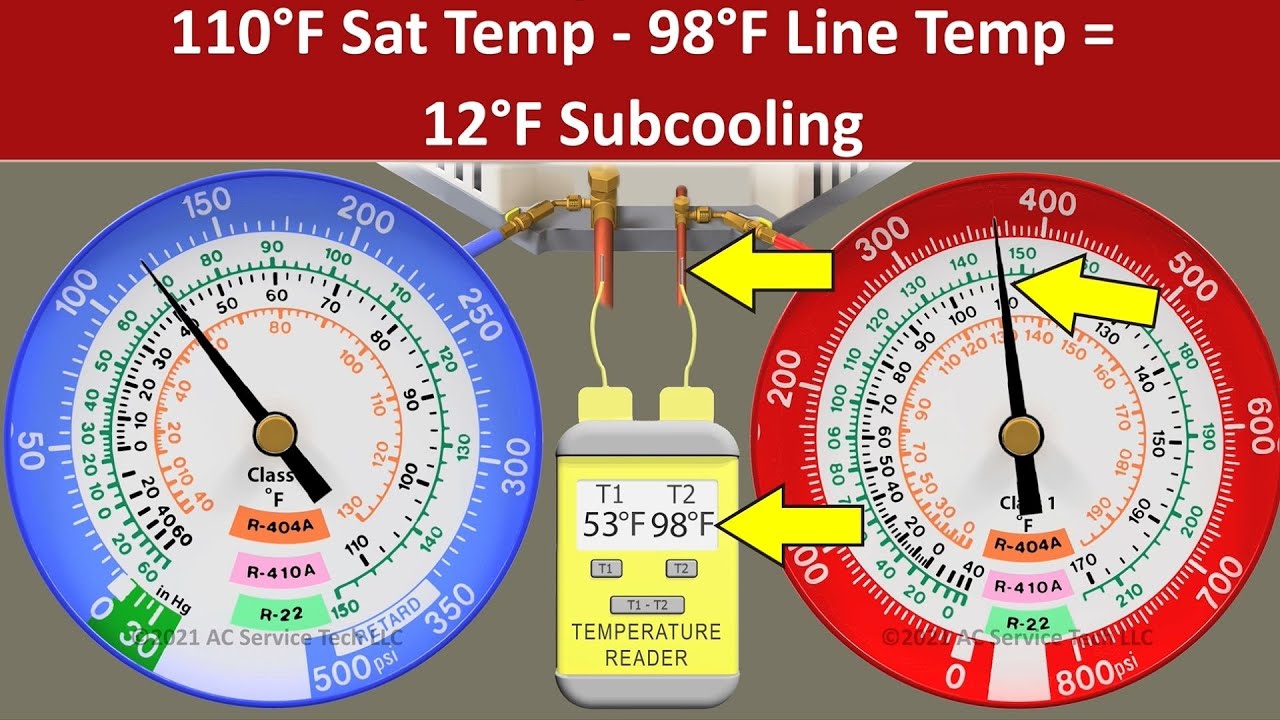

Figuring out Superheat and Subcooling: The chart helps decide the superheat (the temperature distinction between the refrigerant gasoline on the compressor suction and its saturation temperature on the identical stress) and subcooling (the temperature distinction between the liquid refrigerant on the condenser outlet and its saturation temperature on the identical stress). Optimum superheat and subcooling values are important for environment friendly system operation. An excessive amount of or too little of both can point out issues like refrigerant leaks, restricted airflow, or defective elements.

-

Diagnosing System Points: Deviations from the anticipated pressure-temperature relationship indicated on the chart can level to varied issues, together with:

- Low Refrigerant Cost: Low stress on each the excessive and low sides signifies a possible refrigerant leak.

- Excessive Refrigerant Cost: Excessive stress on either side suggests an overcharge.

- Restricted Airflow: Excessive discharge stress and low suction stress might point out restricted airflow by the condenser or evaporator coil.

- Compressor Points: Excessive discharge stress and regular suction stress can counsel a failing compressor.

- Soiled Filters: Restricted airflow attributable to soiled filters can result in related stress readings as restricted airflow by coils.

- Enlargement Valve Issues: Malfunctioning growth valves can result in inconsistent stress readings throughout the system.

-

Charging the System: The chart assists technicians in precisely charging the system with the right amount of refrigerant. By measuring the stress and temperature, they’ll decide if the system is undercharged, overcharged, or correctly charged.

Sensible Functions of the 410A Stress Chart

The 410A mini-split stress chart is an indispensable instrument for HVAC technicians. Its purposes lengthen past easy diagnostics; it is essential for:

-

System Commissioning: In the course of the preliminary set up and commissioning of a mini-split system, the chart ensures the system is correctly charged and working throughout the producer’s specs.

-

Routine Upkeep: Common stress checks utilizing the chart throughout routine upkeep can determine potential issues earlier than they escalate into main failures, saving money and time.

-

Troubleshooting and Restore: As talked about earlier, the chart is significant in diagnosing numerous system malfunctions, guiding technicians in direction of the foundation reason behind the issue and facilitating efficient repairs.

-

Efficiency Optimization: By making certain optimum superheat and subcooling values, the chart contributes to maximizing system effectivity and minimizing power consumption.

Elements Affecting Stress Readings:

It is essential to keep in mind that a number of components can affect the stress readings, and these should be thought-about when decoding the chart:

-

Ambient Temperature: The ambient temperature considerably impacts the system’s working stress. Greater ambient temperatures result in larger pressures.

-

System Load: The heating or cooling load positioned on the system additionally impacts stress. Greater hundreds typically end in larger pressures.

-

Altitude: Altitude impacts the boiling level of the refrigerant, and due to this fact the stress. Greater altitudes typically end in decrease pressures.

-

Refrigerant Purity: Contaminants within the refrigerant can have an effect on its thermodynamic properties and stress readings.

-

Accuracy of Gauges: The accuracy of the stress gauges used is essential for dependable readings. Common calibration of gauges is crucial.

Past the Chart: Different Diagnostic Instruments and Methods

Whereas the stress chart is an important instrument, it isn’t the one methodology for diagnosing mini-split system issues. Different diagnostic instruments and strategies embody:

-

Temperature Measurements: Measuring temperatures at numerous factors within the system (suction line, liquid line, condenser outlet, evaporator inlet) gives further information for correct prognosis.

-

Amperage Readings: Measuring the compressor amperage can reveal potential compressor points.

-

Visible Inspections: Cautious visible inspection of the system for leaks, broken elements, and restricted airflow is crucial.

-

Superheat and Subcooling Calculations: Correct calculation of superheat and subcooling values is essential for confirming correct system operation.

Security Precautions When Utilizing the Stress Chart:

Working with refrigerants requires strict adherence to security protocols. All the time:

-

Put on acceptable private protecting tools (PPE): This contains security glasses, gloves, and respiratory safety.

-

Work in a well-ventilated space: R-410A is heavier than air and may displace oxygen in poorly ventilated areas.

-

Comply with producer’s directions: All the time consult with the producer’s directions for particular system necessities and security procedures.

-

Correctly deal with and get rid of refrigerant: Refrigerant ought to be dealt with and disposed of in line with native rules and environmental pointers.

Conclusion:

The 410A mini-split stress chart is a cornerstone of efficient mini-split system prognosis, upkeep, and restore. By understanding the rules behind the chart and its sensible purposes, HVAC technicians can guarantee optimum system efficiency, determine potential issues early on, and supply environment friendly and efficient service. Nonetheless, it is essential to keep in mind that the chart is only one instrument in a broader diagnostic arsenal. Combining stress readings with different diagnostic strategies and adhering to strict security precautions ensures correct diagnoses and protected working practices. Correct coaching and expertise are important for the proficient use of the 410A stress chart and the efficient upkeep and restore of mini-split programs.

Closure

Thus, we hope this text has supplied beneficial insights into Decoding the 410A Mini Break up Stress Chart: A Complete Information. We thanks for taking the time to learn this text. See you in our subsequent article!