Decoding The BladeHQ Metal Comparability Chart: A Deep Dive Into Knife Metal

Decoding the BladeHQ Metal Comparability Chart: A Deep Dive into Knife Metal

Associated Articles: Decoding the BladeHQ Metal Comparability Chart: A Deep Dive into Knife Metal

Introduction

With nice pleasure, we’ll discover the intriguing subject associated to Decoding the BladeHQ Metal Comparability Chart: A Deep Dive into Knife Metal. Let’s weave attention-grabbing data and provide recent views to the readers.

Desk of Content material

Decoding the BladeHQ Metal Comparability Chart: A Deep Dive into Knife Metal

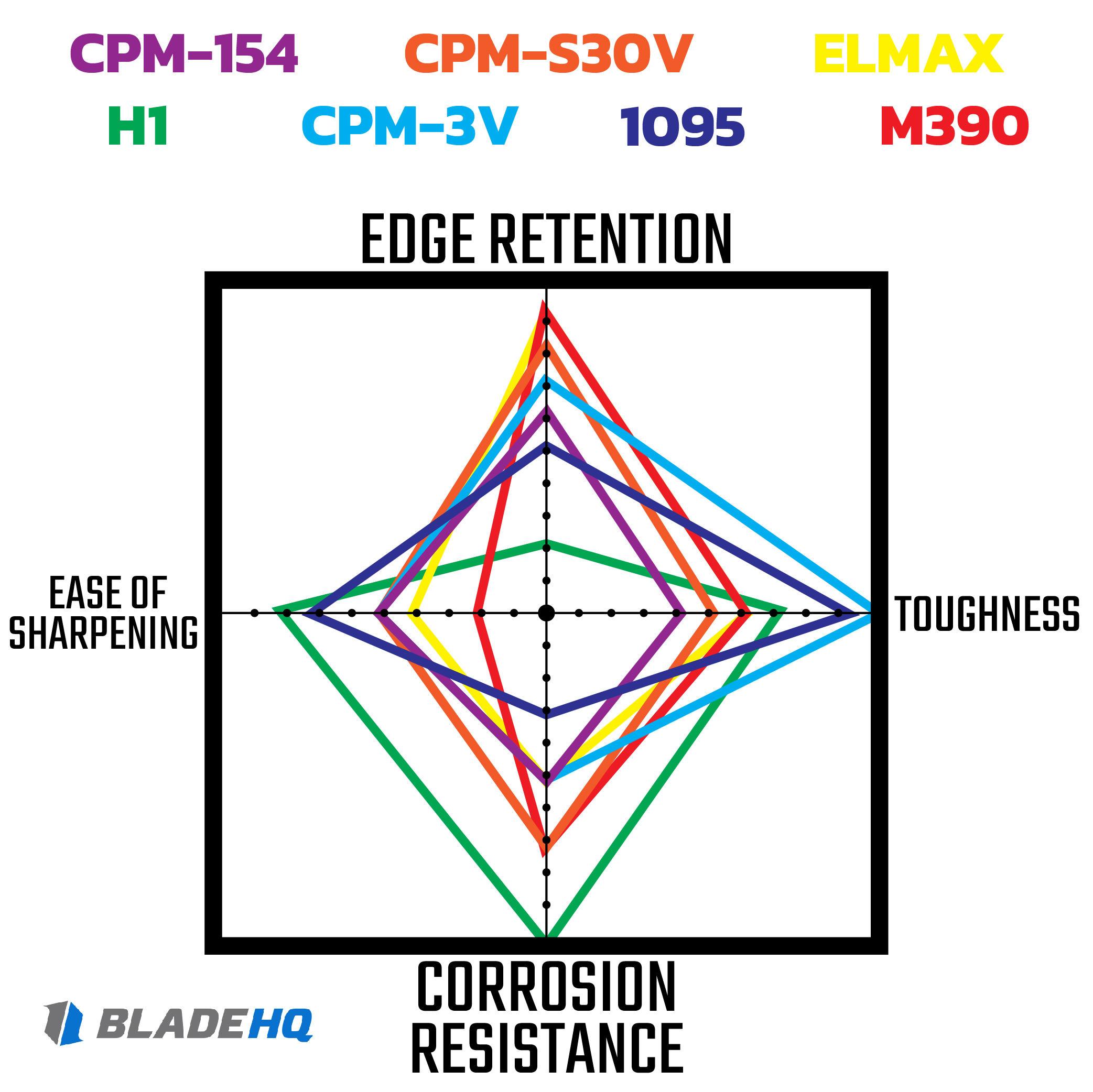

BladeHQ’s metal comparability chart is a precious useful resource for knife lovers, offering a concise overview of the properties of varied metal sorts generally utilized in knife manufacturing. Nevertheless, understanding and decoding this chart requires greater than a cursory look. This text delves deep into the chart’s intricacies, explaining the important thing parameters, clarifying the nuances of metal efficiency, and finally serving to you make knowledgeable selections when deciding on a knife primarily based on its metal composition.

Understanding the Parameters:

The BladeHQ chart usually lists a number of key properties of various metal grades, every contributing to the general efficiency of a knife blade. These parameters, typically expressed numerically, are essential for evaluating steels:

-

Hardness (HRC): Measured on the Rockwell Hardness C scale, this means a metal’s resistance to indentation. Larger HRC values usually translate to larger edge retention (means to carry a pointy edge longer), however typically on the expense of toughness (resistance to chipping or breaking). A steadiness is essential; excessively laborious metal may be brittle. The chart usually reveals a variety somewhat than a single worth, reflecting variations in warmth remedy and manufacturing processes.

-

Put on Resistance: Intently associated to hardness, this parameter signifies how nicely the metal resists abrasion and put on throughout chopping. Steels with superior put on resistance preserve sharpness for longer durations, significantly when used on more durable supplies. That is typically implied by the hardness ranking however can fluctuate because of different alloying parts.

-

Toughness: This measures a metal’s resistance to fracturing or chipping underneath affect or stress. Harder steels are extra resilient to unintentional impacts and are most well-liked for duties involving heavy use or potential abuse. A steadiness between hardness and toughness is important for a flexible knife.

-

Corrosion Resistance: This means the metal’s means to withstand rust and degradation because of publicity to moisture and different corrosive brokers. Excessive corrosion resistance is important for knives utilized in moist environments or saved improperly. That is typically influenced by the presence of chromium and different alloying parts.

-

Stain Resistance: It is a subset of corrosion resistance, particularly specializing in the metal’s means to withstand floor staining. Whereas not at all times explicitly listed, it is implied by the corrosion resistance ranking. Excessive stain resistance is aesthetically necessary and prevents discoloration.

-

Edge Retention: As talked about, this refers to a metal’s means to keep up its sharpness over time. Excessive edge retention interprets to fewer sharpening periods, making the knife extra handy for frequent use. Hardness is a big issue, however different parts additionally contribute.

-

Machinability: This parameter displays how simply the metal may be machined and formed throughout the manufacturing course of. Whereas indirectly impacting the end-user, it influences the price and manufacturing feasibility of a knife. It is much less crucial for the typical client however related for understanding potential worth fluctuations.

Deciphering the Metal Grades:

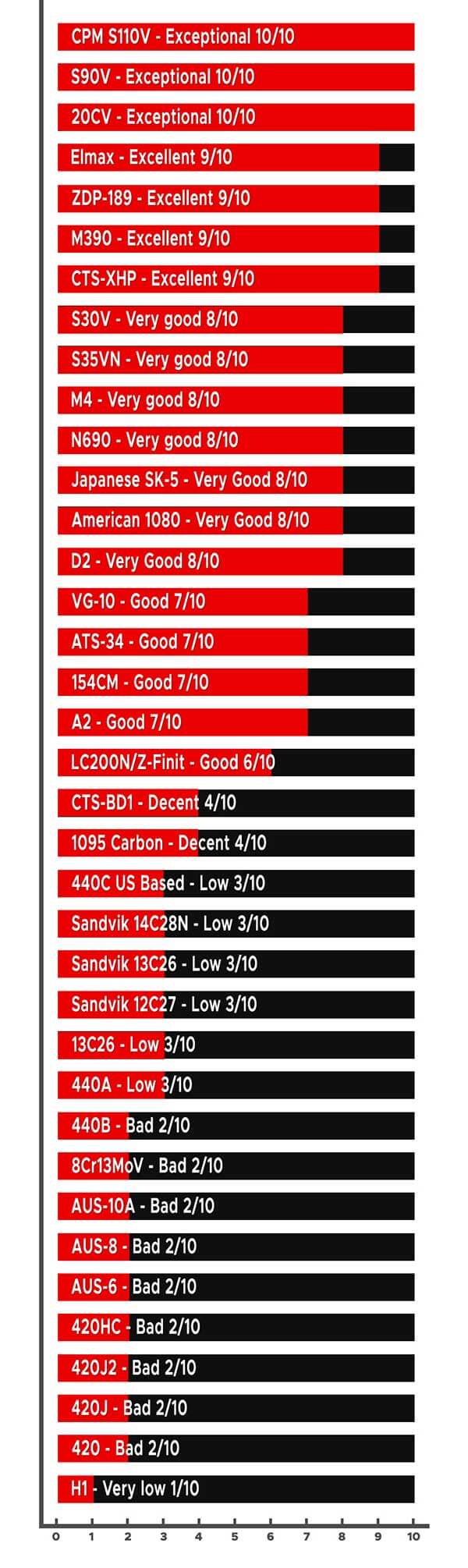

The BladeHQ chart lists quite a few metal grades, every with distinctive traits and compositions. Some frequent examples and their typical efficiency traits embrace:

-

1095 Excessive Carbon Metal: A comparatively cheap, high-carbon metal recognized for its glorious edge retention and ease of sharpening. Nevertheless, it lacks vital corrosion resistance and requires common upkeep.

-

440C Stainless Metal: A extensively used chrome steel providing good corrosion resistance, reasonable edge retention, and affordable toughness. It is a versatile choice for a lot of purposes.

-

AUS-8 Stainless Metal: Just like 440C in efficiency, AUS-8 is usually barely extra corrosion-resistant and presents higher edge retention.

-

VG-10 Stainless Metal: A Japanese chrome steel recognized for its glorious edge retention, good corrosion resistance, and comparatively excessive toughness. It is a common alternative for high-performance knives.

-

D2 Instrument Metal: A high-carbon, high-chromium software metal famend for distinctive edge retention and put on resistance. Nevertheless, it is much less robust than many stainless steels and requires cautious upkeep to forestall rust.

-

S30V Stainless Metal: A premium chrome steel recognized for its glorious steadiness of edge retention, toughness, and corrosion resistance. It is a common alternative for high-end knives however may be dearer.

-

CPM-S30V: A powder metallurgy model of S30V, providing improved consistency and finer grain construction, resulting in probably even higher efficiency traits.

-

M390 Stainless Metal: One other high-performance powder metallurgy metal recognized for its distinctive edge retention, toughness, and corrosion resistance. It is typically thought-about a top-tier metal for knives.

-

Crucible 20CV: A more recent metal that boasts spectacular edge retention, toughness, and corrosion resistance, rivaling M390 in lots of respects.

Deciphering the Chart and Making Knowledgeable Selections:

The BladeHQ metal comparability chart should not be considered as a definitive rating system. The "greatest" metal relies upon closely on the supposed use of the knife. A chef’s knife may prioritize corrosion resistance and edge retention, whereas a looking knife may emphasize toughness and edge retention above all else. A folding pocket knife must steadiness all properties.

Think about the next when utilizing the chart:

-

Meant Use: Determine the first duties the knife will carry out. It will information your collection of applicable metal properties.

-

Upkeep: Be real looking about your willingness to keep up the knife. Excessive-carbon steels require extra frequent sharpening and care than stainless steels.

-

Funds: Premium steels like S30V and M390 provide superior efficiency however come at a better worth.

-

Steadiness: Acknowledge that an ideal steadiness of all properties isn’t achievable. Prioritize probably the most crucial attributes in your supposed use.

Past the Numbers:

The BladeHQ chart supplies precious quantitative knowledge, but it surely would not seize all the pieces. Components like warmth remedy, blade geometry, and general knife design considerably affect efficiency. A poorly heat-treated blade created from glorious metal will underperform in comparison with a well-heat-treated blade created from a barely much less spectacular metal. Equally, blade geometry impacts chopping efficiency, and general design impacts ergonomics and usefulness.

Conclusion:

The BladeHQ metal comparability chart is a useful software, but it surely’s solely a part of the equation. By understanding the parameters, the nuances of various metal grades, and the significance of balancing properties, you need to use this chart to make knowledgeable selections when deciding on a knife that meets your particular wants and expectations. Bear in mind to contemplate the supposed use, upkeep necessities, finances, and the general knife design along with the metal properties to decide on the right knife in your wants. Do not hesitate to analysis particular person metal grades additional to achieve a deeper understanding of their strengths and weaknesses earlier than making your buy. The chart is a place to begin, not the ultimate reply.

Closure

Thus, we hope this text has supplied precious insights into Decoding the BladeHQ Metal Comparability Chart: A Deep Dive into Knife Metal. We thanks for taking the time to learn this text. See you in our subsequent article!