Decoding The Fastener World: A Complete Information To Materials Grade Charts

Decoding the Fastener World: A Complete Information to Materials Grade Charts

Associated Articles: Decoding the Fastener World: A Complete Information to Materials Grade Charts

Introduction

With nice pleasure, we’ll discover the intriguing subject associated to Decoding the Fastener World: A Complete Information to Materials Grade Charts. Let’s weave fascinating info and provide contemporary views to the readers.

Desk of Content material

Decoding the Fastener World: A Complete Information to Materials Grade Charts

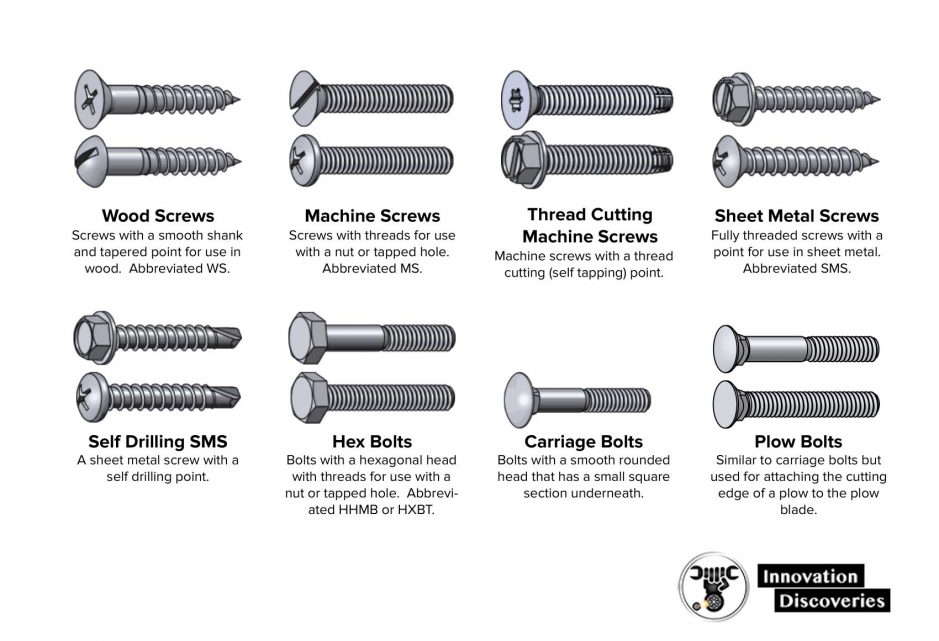

Fasteners – seemingly insignificant elements – are the spine of numerous constructions and machines. From the smallest screws holding electronics collectively to the huge bolts securing bridges, these seemingly easy components play a vital function in making certain structural integrity and operational security. The efficiency and longevity of those fasteners are instantly linked to the fabric they’re constituted of, which is usually specified by a cloth grade. Understanding these materials grades is essential for engineers, designers, and anybody concerned in deciding on fasteners for particular functions. This text offers a complete information to fastener materials grade charts, explaining the varied supplies, their properties, and easy methods to interpret the related grading programs.

The Significance of Materials Grade Choice

The selection of fastener materials is not arbitrary. It relies upon closely on the applying’s working atmosphere and the required efficiency traits. Elements to contemplate embrace:

- Power: The fastener should face up to the utilized load with out failure. This consists of tensile energy, shear energy, and fatigue resistance.

- Corrosion Resistance: Publicity to moisture, chemical compounds, or different corrosive components necessitates the choice of corrosion-resistant supplies.

- Temperature Resistance: Excessive or low working temperatures can have an effect on the fabric’s energy and ductility.

- Price: Materials value is a big issue, particularly in high-volume functions. A stability have to be struck between value and efficiency.

- Particular Utility Necessities: Sure functions could require particular materials properties, corresponding to non-magnetic properties for delicate tools or biocompatibility for medical implants.

Frequent Fastener Supplies and Their Grades

A number of supplies are generally used for fasteners, every with its personal set of properties and designated grade. Understanding these grades is paramount for correct choice.

1. Carbon Metal:

Carbon metal is the commonest and cost-effective materials for fasteners. Its grade is usually indicated by a quantity, with greater numbers representing greater energy. Frequent grades embrace:

- Grade 2: Low-strength carbon metal, appropriate for general-purpose functions the place load necessities are minimal. Typically used for light-duty functions and inside use.

- Grade 5: Medium-strength carbon metal, providing improved energy and hardness in comparison with Grade 2. Broadly utilized in numerous functions requiring average energy.

- Grade 8: Excessive-strength carbon metal, offering considerably better tensile energy and fatigue resistance. Appropriate for heavy-duty functions and important structural elements.

- Different Grades: Numerous different grades exist, corresponding to Grade 1, Grade 4, and specialised grades for particular functions. These grades typically incorporate alloying components to boost particular properties.

2. Stainless Metal:

Chrome steel provides glorious corrosion resistance, making it supreme for out of doors and harsh environments. A number of grades exist, with variations in chromium, nickel, and molybdenum content material influencing their properties:

- 304 Stainless Metal: A standard austenitic chrome steel identified for its good corrosion resistance and ductility. Broadly utilized in meals processing, chemical industries, and architectural functions.

- 316 Stainless Metal: Just like 304 however with added molybdenum for improved resistance to chloride corrosion, making it appropriate for marine environments and functions uncovered to saltwater.

- 410 Stainless Metal: A martensitic chrome steel, providing greater energy than austenitic grades however decrease corrosion resistance. Typically utilized in functions requiring excessive hardness and put on resistance.

- Different Grades: Many different chrome steel grades exist, every tailor-made for particular corrosion resistance and energy necessities. These are sometimes specified by their UNS (Unified Numbering System) designation.

3. Alloy Metal:

Alloy steels incorporate numerous alloying components (e.g., chromium, molybdenum, nickel) to boost particular properties like energy, toughness, and corrosion resistance. These are sometimes specified by their alloy designation (e.g., 4140, 8740). The grade signifies the particular warmth remedy and ensuing mechanical properties.

4. Brass:

Brass, an alloy of copper and zinc, provides good corrosion resistance and machinability. It’s typically utilized in functions requiring non-sparking properties or good electrical conductivity. Grades are normally specified by the copper-zinc ratio.

5. Aluminum:

Aluminum fasteners are light-weight and provide good corrosion resistance. Numerous alloys exist, with grades specified by their alloy designation (e.g., 6061, 7075). They’re generally utilized in aerospace and automotive functions.

6. Different Supplies:

Different supplies used for fasteners embrace titanium (excessive strength-to-weight ratio, glorious corrosion resistance), nylon (for non-metallic, non-conductive functions), and numerous specialised polymers.

Decoding Materials Grade Charts

Materials grade charts usually checklist the fabric, grade, and key mechanical properties. These properties embrace:

- Tensile Power: The utmost stress a cloth can face up to earlier than it begins to deform completely.

- Yield Power: The stress at which a cloth begins to deform plastically.

- Shear Power: The utmost stress a cloth can face up to earlier than it fails in shear.

- Hardness: A measure of a cloth’s resistance to indentation or scratching.

- Elongation: The proportion improve in size a cloth undergoes earlier than fracture.

Understanding these properties is essential for choosing the suitable fastener for a given software. The next tensile energy signifies a stronger fastener, whereas greater yield energy ensures much less everlasting deformation below load. Shear energy is essential for functions involving shear forces.

Examples of Materials Grade Charts:

Whereas particular charts range relying on the producer and normal, they often comply with an identical format. A typical chart would possibly embrace columns for:

| Materials | Grade | Tensile Power (MPa) | Yield Power (MPa) | Shear Power (MPa) | Hardness | Elongation (%) | Utility Notes |

|---|---|---|---|---|---|---|---|

| Carbon Metal | Grade 2 | 310 | 230 | 210 | 80-90 Brinell | 20 | Normal objective |

| Carbon Metal | Grade 5 | 830 | 620 | 590 | 200-220 Brinell | 12 | Heavy obligation |

| Stainless Metal | 304 | 515 | 205 | 345 | 150-170 Brinell | 40 | Corrosion resistant |

| Stainless Metal | 316 | 515 | 205 | 345 | 150-170 Brinell | 40 | Marine functions |

Conclusion:

Choosing the proper fastener materials and grade is paramount for making certain the protection and reliability of any construction or machine. This text offers a foundational understanding of varied supplies, their properties, and easy methods to interpret materials grade charts. At all times consult with the producer’s specs and related business requirements when deciding on fasteners for particular functions. Failure to take action can result in untimely failure, structural harm, and potential security hazards. By rigorously contemplating the working atmosphere, load necessities, and materials properties, engineers and designers can make sure the choice of acceptable fasteners for optimum efficiency and longevity. Do not forget that this can be a common overview, and particular materials grades and their properties could range barely relying on the producer and relevant requirements. At all times seek the advice of related requirements and datasheets for exact info earlier than making essential design choices.

Closure

Thus, we hope this text has supplied useful insights into Decoding the Fastener World: A Complete Information to Materials Grade Charts. We hope you discover this text informative and useful. See you in our subsequent article!