Decoding The Labyrinth: A Complete Information To Hyperlink Seal Sizing Charts

Decoding the Labyrinth: A Complete Information to Hyperlink Seal Sizing Charts

Associated Articles: Decoding the Labyrinth: A Complete Information to Hyperlink Seal Sizing Charts

Introduction

With nice pleasure, we are going to discover the intriguing matter associated to Decoding the Labyrinth: A Complete Information to Hyperlink Seal Sizing Charts. Let’s weave fascinating info and provide recent views to the readers.

Desk of Content material

Decoding the Labyrinth: A Complete Information to Hyperlink Seal Sizing Charts

Hyperlink seals, also called rotary shaft seals, are essential elements in numerous industrial functions, stopping leakage between rotating shafts and stationary housings. Their correct sizing is paramount for making certain efficient sealing, stopping expensive downtime, and sustaining operational effectivity. Nevertheless, navigating the complexities of hyperlink seal sizing charts may be daunting, even for knowledgeable engineers. This text goals to demystify the method, offering a complete information to understanding and using these charts to pick out the optimum seal on your particular utility.

Understanding the Fundamentals of Hyperlink Seal Design and Performance:

Earlier than delving into sizing charts, it is essential to know the basic ideas behind hyperlink seal operation. Hyperlink seals usually include a number of key elements:

- Lip Seal: That is the first sealing ingredient, constituted of elastomeric supplies like nitrile (NBR), ethylene propylene (EPDM), fluoroelastomer (FKM), or silicone. The lip’s design and materials are essential for reaching a good seal in opposition to the shaft.

- Seal Housing: This element supplies structural help for the seal and homes the lip seal. It is usually constituted of steel or a sturdy polymer.

- Spring (Non-compulsory): Some hyperlink seals incorporate a spring to take care of constant lip contact with the shaft, compensating for put on and thermal growth.

- Hyperlink(s): These are the defining function of a hyperlink seal, connecting particular person seal components to create a steady seal throughout a number of shaft sections or when the shaft has a major diameter change. They permit flexibility and lodging for misalignment.

Key Parameters Influencing Hyperlink Seal Choice:

Choosing the proper hyperlink seal includes contemplating a number of essential parameters, all of that are usually mirrored in sizing charts:

- Shaft Diameter: That is probably the most basic parameter. The seal’s interior diameter should precisely match the shaft diameter to make sure correct sealing. Charts usually specify a variety of acceptable shaft diameters for every seal dimension.

- Housing Bore Diameter: This refers back to the interior diameter of the housing the place the seal is put in. The seal’s outer diameter should be barely smaller than the housing bore to permit for correct set up and forestall injury.

- Seal Width (Size): This parameter determines the seal’s contact size with the shaft. An extended seal typically supplies higher sealing efficiency however might require more room.

- Seal Materials: The selection of elastomer is dependent upon the working situations, together with temperature, strain, and the character of the sealed fluid. Every materials has particular temperature and chemical resistance properties.

- Working Strain: The seal should have the ability to stand up to the interior strain of the system with out leaking. Sizing charts usually specify the utmost working strain for every seal dimension and materials.

- Working Temperature: Temperature extremes can have an effect on the elastomer’s properties, resulting in seal failure. Charts point out the temperature vary for which every seal is appropriate.

- Fluid Compatibility: The seal materials should be appropriate with the sealed fluid to stop degradation and leakage. Producers present compatibility charts to information choice.

- Pace: The rotational pace of the shaft influences the friction and put on on the seal. Excessive-speed functions might require specialised seals with enhanced sturdiness.

- Sort of Seal: Hyperlink seals themselves are available in varied configurations, together with single-acting, double-acting, and specialised designs for particular functions (e.g., high-pressure, high-temperature).

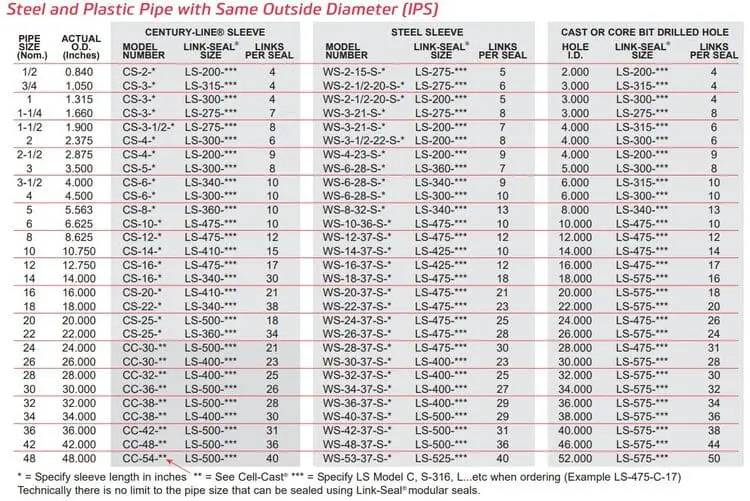

Deciphering Hyperlink Seal Sizing Charts:

Hyperlink seal sizing charts are usually offered in tabular format. They normally set up info by seal dimension, itemizing the related parameters for every dimension. Here is a breakdown of easy methods to interpret a typical chart:

| Seal Dimension | Shaft Diameter (min-max) | Housing Bore Diameter (min-max) | Seal Width | Materials Choices | Max. Strain | Max. Temperature | Notes |

|---|---|---|---|---|---|---|---|

| 10x20x5 | 10.0-10.2 mm | 20.0-20.2 mm | 5 mm | NBR, EPDM, FKM | 10 bar | 100°C | Single-acting |

| 15x25x7 | 15.0-15.2 mm | 25.0-25.2 mm | 7 mm | NBR, EPDM | 7 bar | 80°C | Double-acting |

| 20x30x10 | 20.0-20.2 mm | 30.0-30.2 mm | 10 mm | NBR, FKM, Viton | 15 bar | 120°C | Excessive-temperature |

Deciphering the Chart:

- Seal Dimension: This can be a manufacturer-specific designation that uniquely identifies the seal.

- Shaft Diameter (min-max): This vary signifies the suitable shaft diameter for the given seal dimension. The shaft diameter ought to fall inside this vary.

- Housing Bore Diameter (min-max): This vary specifies the suitable housing bore diameter. The housing bore must be barely bigger than the seal’s outer diameter.

- Seal Width: That is the axial size of the seal.

- Materials Choices: This lists the out there elastomer supplies for the seal.

- Max. Strain: This means the utmost working strain the seal can stand up to.

- Max. Temperature: This exhibits the utmost working temperature for the seal.

- Notes: This part might embrace extra details about the seal’s design, options, or limitations.

Past the Primary Chart: Superior Issues:

Whereas fundamental sizing charts present a place to begin, choosing the optimum hyperlink seal usually requires contemplating extra nuanced components:

- Dynamic vs. Static Seals: The chart ought to make clear whether or not the seal is designed for static or dynamic functions. Dynamic seals deal with rotating shafts, whereas static seals are for stationary functions.

- Floor End: The shaft’s floor end considerably impacts seal life and efficiency. A smoother floor typically ends in higher seal efficiency.

- Set up Strategies: Correct set up is essential for seal effectiveness. The chart might present steerage on set up methods or discuss with separate set up directions.

- Particular Design Options: Some hyperlink seals incorporate extra options, resembling built-in wipers or secondary seals, to reinforce efficiency in difficult environments. These options must be thought of throughout choice.

Conclusion:

Mastering hyperlink seal sizing charts is crucial for engineers and technicians working with rotating shaft functions. This text offered a complete overview of the important thing parameters influencing seal choice, defined easy methods to interpret sizing charts, and highlighted superior concerns for optimum seal efficiency. Bear in mind to all the time seek the advice of the producer’s particular sizing charts and documentation for probably the most correct and dependable info. Correct seal choice not solely prevents leaks and downtime but in addition contributes considerably to the general effectivity and longevity of your tools. By fastidiously contemplating all related components and using the data offered in sizing charts, you’ll be able to make sure the choice of probably the most applicable hyperlink seal on your particular utility, in the end resulting in a extra sturdy and dependable system.

Closure

Thus, we hope this text has offered useful insights into Decoding the Labyrinth: A Complete Information to Hyperlink Seal Sizing Charts. We respect your consideration to our article. See you in our subsequent article!