Decoding The Mysteries Of 5D Bend Dimensions: A Complete Information

Decoding the Mysteries of 5D Bend Dimensions: A Complete Information

Associated Articles: Decoding the Mysteries of 5D Bend Dimensions: A Complete Information

Introduction

With nice pleasure, we are going to discover the intriguing matter associated to Decoding the Mysteries of 5D Bend Dimensions: A Complete Information. Let’s weave attention-grabbing data and supply contemporary views to the readers.

Desk of Content material

Decoding the Mysteries of 5D Bend Dimensions: A Complete Information

The world of sheet metallic fabrication is rife with intricate calculations and exact measurements. One essential facet usually requiring cautious consideration is bend deduction, significantly in eventualities involving advanced 5D bends. Whereas easier bends may be calculated with comparatively simple formulation, the complexity of 5D bends necessitates a extra nuanced method, usually aided by specialised charts and software program. This text delves into the intricacies of 5D bend dimensions, exploring the challenges, the options provided by 5D bend dimension PDFs, and the essential concerns for correct fabrication.

Understanding the 5D Bend Conundrum

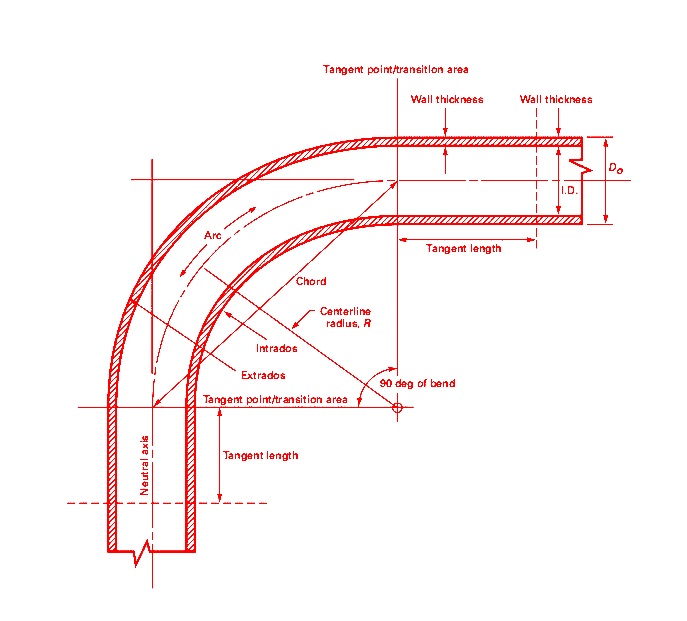

Earlier than diving into the specifics of 5D bend dimension charts, it is important to grasp what constitutes a 5D bend. In contrast to easier 2D or 3D bends which contain bending in a single or two planes, a 5D bend introduces extra levels of freedom, involving a number of bends throughout completely different axes and planes. This complexity stems from the interplay of a number of bend radii, bend angles, and materials properties. These interactions create a major problem in precisely predicting the ultimate dimensions of the bent half. A slight miscalculation can result in vital discrepancies, rendering the fabricated half unusable.

The "5D" designation itself is not a universally standardized time period. It is extra of a descriptive label highlighting the multi-dimensional nature of the bending course of. The 5 dimensions sometimes discuss with:

- X-axis bend: The first bend alongside the size of the sheet.

- Y-axis bend: A bend perpendicular to the X-axis.

- Z-axis bend: A bend that provides depth or top to the half.

- Bend radius: The radius of the bend, considerably influencing the ultimate dimensions.

- Materials thickness: The thickness of the sheet metallic, a crucial issue affecting bend deformation.

These 5 parameters work together in a non-linear vogue, making guide calculation extremely difficult. That is the place 5D bend dimension PDFs turn out to be invaluable instruments.

The Function of 5D Bend Dimension PDFs

5D bend dimension PDFs supply pre-calculated information tables or interactive charts that simplify the advanced calculations concerned in 5D bends. These PDFs sometimes current information organized round numerous combos of the 5 key parameters talked about above. By inputting the particular values in your venture – materials thickness, bend radii, and bend angles – you may shortly find the corresponding bend deduction values. This enables for correct dedication of the flat clean dimension required to realize the specified closing dimensions.

The worth of those PDFs lies of their skill to:

- Scale back calculation errors: Guide calculations are susceptible to errors, particularly with advanced geometries. PDFs eradicate this human error issue.

- Save time and sources: The time saved in calculations interprets instantly into elevated productiveness and lowered venture prices.

- Enhance accuracy: Pre-calculated information ensures higher precision within the closing product.

- Facilitate standardization: Utilizing a standardized PDF for bend deduction ensures consistency throughout completely different tasks and groups.

- Deal with numerous supplies: Good high quality PDFs account for the completely different materials properties (e.g., springback) of varied sheet metals.

Key Issues When Utilizing 5D Bend Dimension PDFs

Whereas 5D bend dimension PDFs are invaluable instruments, it is essential to make use of them accurately and perceive their limitations:

- Materials properties: The PDF should precisely replicate the properties of the sheet metallic getting used. Make sure the PDF is restricted to the fabric kind and grade.

- Bend radius: The bend radius is a crucial issue. The PDF ought to present information for a variety of bend radii. Utilizing an incorrect radius will result in inaccurate outcomes.

- Bend angle: Correct measurement of the bend angle is important. Slight variations can considerably influence the ultimate dimensions.

- Software program compatibility: Be certain that the PDF is suitable along with your software program and viewing instruments. Some PDFs may require particular software program for correct viewing and interplay.

- Springback: Sheet metallic reveals springback after bending. The PDF ought to account for springback, both by way of pre-calculated values or by offering correction elements. Ignoring springback can result in vital dimensional inaccuracies.

- Tooling: The kind of tooling used (e.g., V-die, radius die) influences the bend. The PDF may supply completely different information units for numerous tooling configurations.

- Tolerance: Perceive the tolerances related to the info within the PDF. Enable for a margin of error throughout fabrication.

Past Easy Charts: Superior Options in 5D Bend Dimension PDFs

Some superior 5D bend dimension PDFs transcend easy lookup tables. They might incorporate options corresponding to:

- Interactive calculators: These enable customers to enter their parameters and obtain on the spot calculations, eliminating the necessity for guide looking out throughout the PDF.

- 3D visualization: Some PDFs present 3D fashions of the bends, permitting for higher visualization of the ultimate product earlier than fabrication.

- Export capabilities: The power to export the calculated information to different software program packages (e.g., CAD software program) streamlines the design course of.

- Materials databases: Integration with materials databases simplifies the collection of the proper materials properties.

Conclusion: Mastering 5D Bends with Precision

5D bends current a major problem in sheet metallic fabrication, requiring exact calculations to realize correct outcomes. 5D bend dimension PDFs are indispensable instruments for overcoming these challenges. By using these PDFs accurately and understanding their limitations, fabricators can considerably enhance the accuracy, effectivity, and cost-effectiveness of their operations. The selection of the best PDF, nevertheless, is paramount. Guarantee the chosen PDF is suitable along with your wants, materials, and tooling, and all the time account for elements like springback and tolerances for optimum outcomes. The pursuit of precision in 5D bending in the end interprets into increased high quality merchandise and a extra streamlined manufacturing course of. Investing time in understanding and using these highly effective instruments is an funding within the success of any sheet metallic fabrication endeavor.

Closure

Thus, we hope this text has offered beneficial insights into Decoding the Mysteries of 5D Bend Dimensions: A Complete Information. We thanks for taking the time to learn this text. See you in our subsequent article!