Decoding The R-410A Superheat Chart: A Complete Information For HVAC Technicians

Decoding the R-410A Superheat Chart: A Complete Information for HVAC Technicians

Associated Articles: Decoding the R-410A Superheat Chart: A Complete Information for HVAC Technicians

Introduction

With enthusiasm, let’s navigate by way of the intriguing matter associated to Decoding the R-410A Superheat Chart: A Complete Information for HVAC Technicians. Let’s weave attention-grabbing data and provide contemporary views to the readers.

Desk of Content material

Decoding the R-410A Superheat Chart: A Complete Information for HVAC Technicians

Refrigerant R-410A is a extensively used refrigerant in trendy air-con and refrigeration methods, identified for its excessive effectivity and comparatively low environmental affect in comparison with older refrigerants like R-22. Understanding its habits, notably its superheat, is essential for environment friendly and dependable system operation. This text delves into the intricacies of R-410A superheat charts, explaining their significance, methods to interpret them, and methods to use this data for troubleshooting and optimum system efficiency.

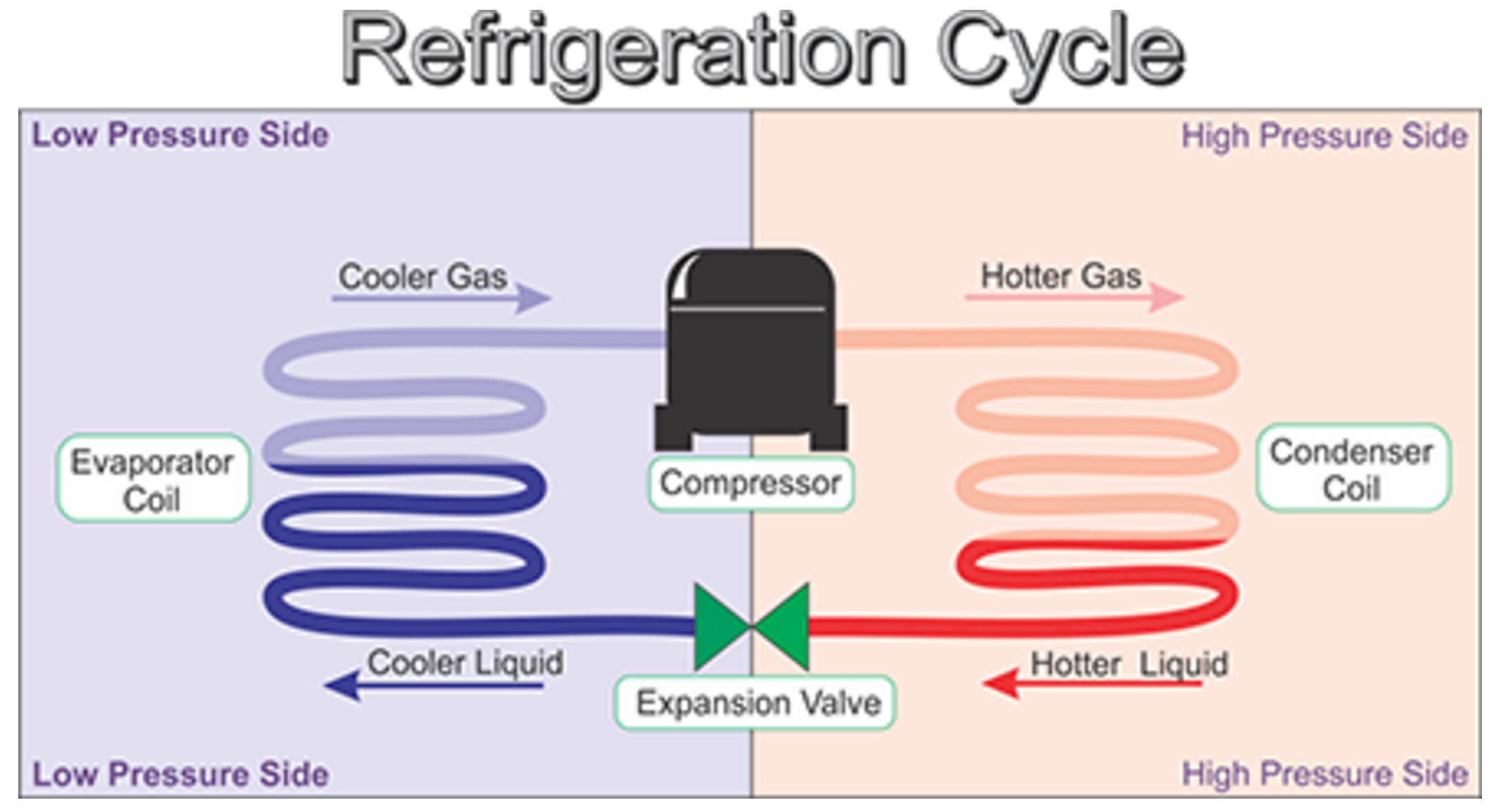

Understanding Superheat and its Significance

Earlier than diving into the chart itself, let’s set up a transparent understanding of superheat. Superheat is the distinction in temperature between the refrigerant’s precise temperature and its saturation temperature at a given stress. In less complicated phrases, it is the quantity the refrigerant is heated above its boiling level.

Why is superheat so necessary? As a result of it immediately impacts the effectivity and longevity of an HVAC system.

-

Inadequate Superheat: Low superheat signifies the refrigerant is near its liquid state. This may result in liquid refrigerant getting into the compressor, inflicting critical injury like slugging, valve failure, and finally, compressor burnout. Liquid refrigerant is incompressible, and forcing it into the compressor can result in catastrophic failure.

-

Extreme Superheat: Excessive superheat, alternatively, whereas not as instantly damaging as low superheat, signifies inefficiency. Extreme superheat means the refrigerant is absorbing extra warmth than needed earlier than it adjustments section from liquid to vapor. This wastes vitality and reduces the system’s cooling capability. It could actually additionally level in direction of issues like inadequate refrigerant cost or restricted airflow over the evaporator coil.

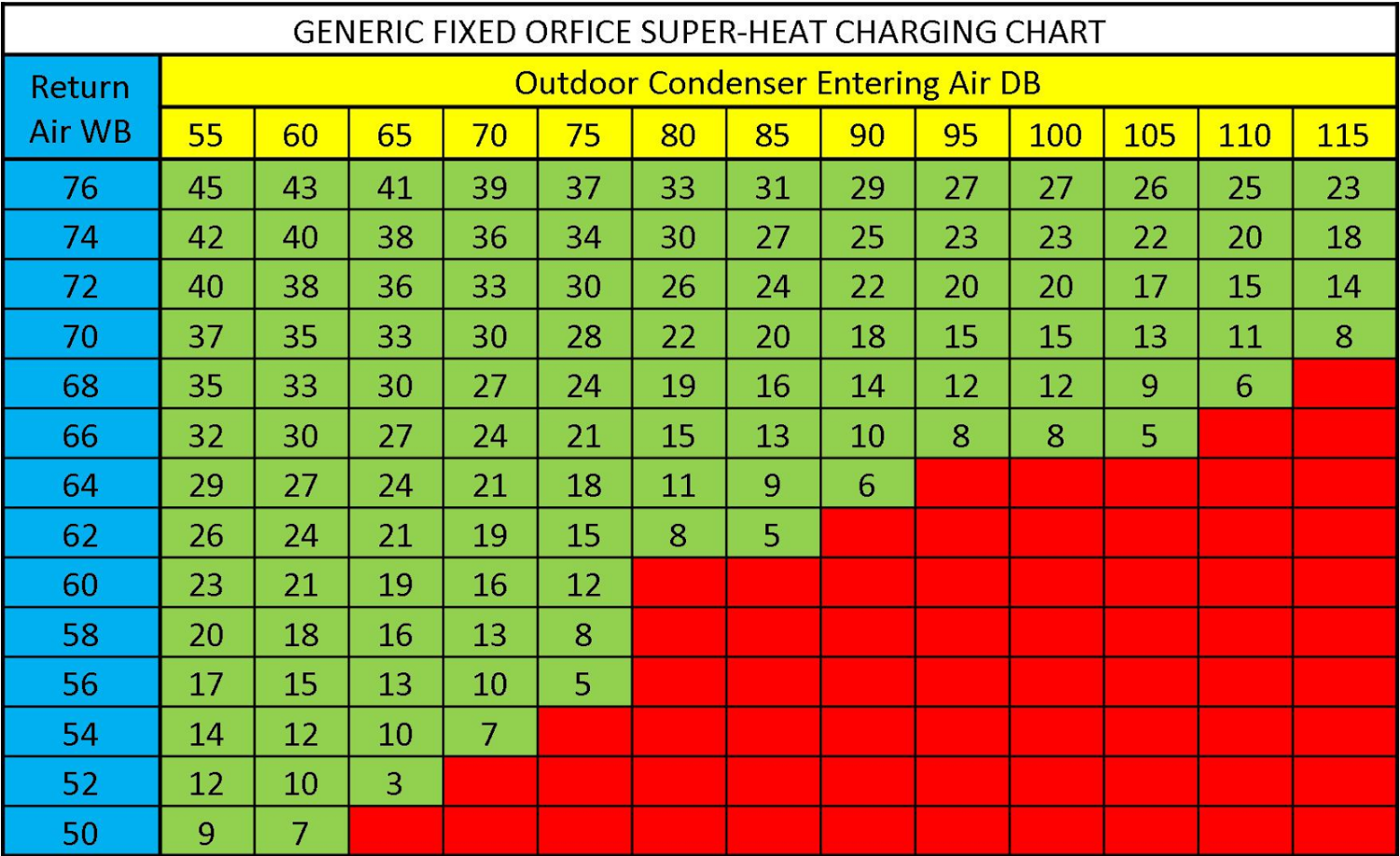

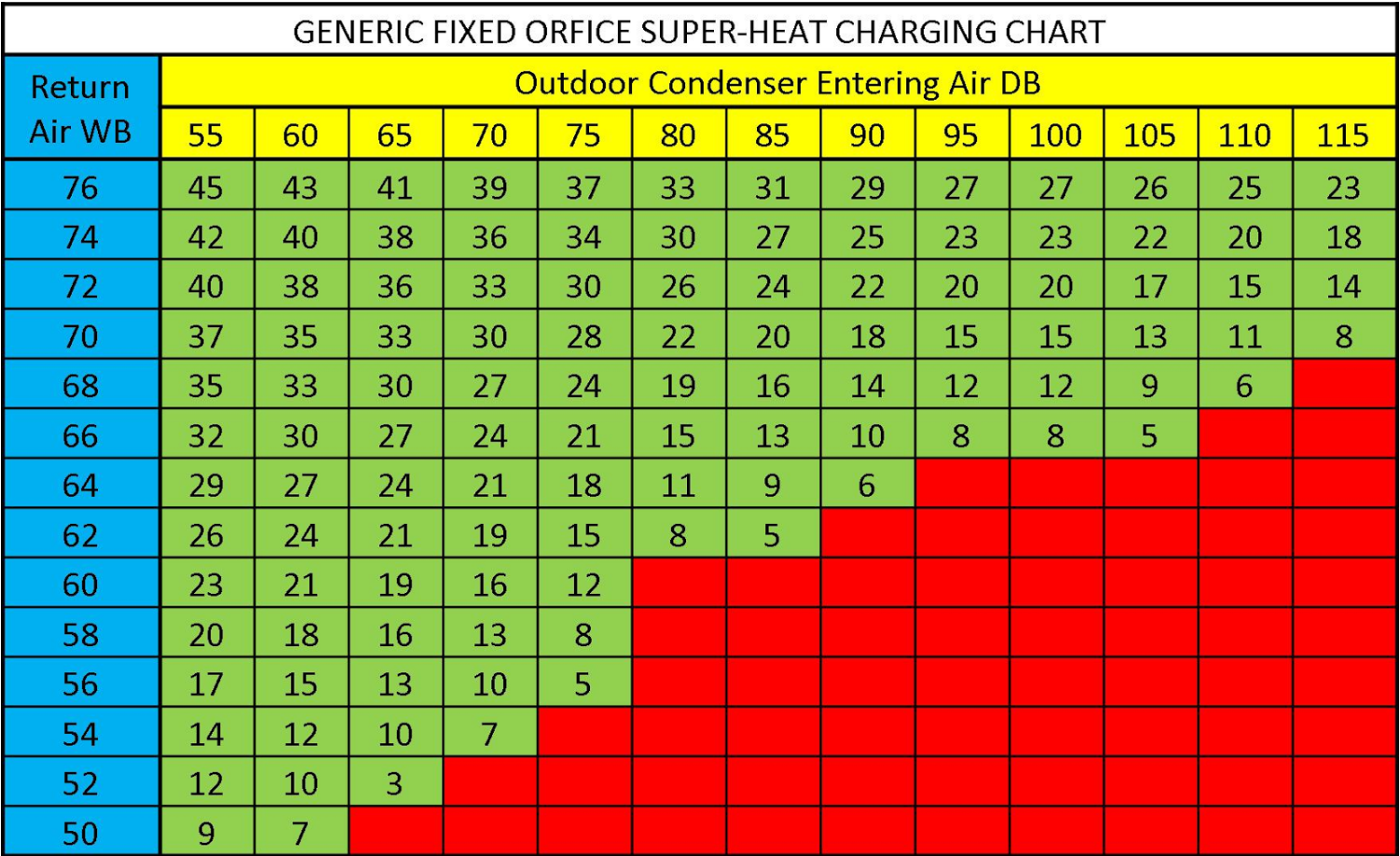

Decoding the R-410A Superheat Chart

R-410A superheat charts sometimes current knowledge in a graphical format, often with stress (often in psig) on the horizontal axis and superheat (in levels Fahrenheit or Celsius) on the vertical axis. Traces of fixed temperature are sometimes included, permitting for fast dedication of superheat given stress and temperature readings. Some charts may also embrace subcooling knowledge, which represents the quantity the refrigerant is cooled under its condensation temperature.

Key Components of an R-410A Superheat Chart:

-

Strain (psig): That is the refrigerant stress measured on the suction line, sometimes simply earlier than the compressor. Correct stress readings are important for utilizing the chart successfully. A correctly calibrated stress gauge is essential.

-

Superheat (°F or °C): That is the important thing parameter to be decided utilizing the chart. It is calculated by subtracting the saturation temperature (obtained from the chart based mostly on the suction line stress) from the precise refrigerant temperature measured on the suction line.

-

Saturation Temperature (°F or °C): That is the temperature at which the refrigerant boils at a given stress. The chart supplies this temperature for every stress worth.

-

Temperature (°F or °C): That is the precise temperature of the refrigerant measured on the suction line utilizing a temperature probe. Accuracy is paramount right here.

Methods to Use the R-410A Superheat Chart:

-

Measure Suction Line Strain: Utilizing a correctly calibrated gauge, measure the stress within the suction line of the refrigeration system.

-

Measure Suction Line Temperature: Use a temperature probe to precisely measure the temperature of the refrigerant within the suction line. Make sure the probe is correctly positioned to acquire a consultant studying.

-

Find Strain on the Chart: Discover the measured stress on the horizontal axis of the superheat chart.

-

Discover Saturation Temperature: Comply with the vertical line from the measured stress to intersect the saturation temperature curve. Notice the saturation temperature at this intersection.

-

Calculate Superheat: Subtract the saturation temperature from the measured suction line temperature. The result’s the superheat. For instance: If the suction line temperature is 50°F and the saturation temperature on the measured stress is 30°F, the superheat is 20°F.

-

Interpret the Outcomes: Evaluate the calculated superheat to the beneficial superheat vary for the particular system. This vary is often specified by the producer and is usually between 10°F and 20°F (5°C and 11°C). Values outdoors this vary point out potential issues.

Troubleshooting with the Superheat Chart:

-

Low Superheat: If the superheat is simply too low (under the beneficial vary), it suggests potential issues similar to:

- Inadequate refrigerant cost: The system would possibly lack refrigerant, resulting in liquid refrigerant getting into the compressor.

- Restricted airflow over the evaporator coil: Filth, particles, or ice buildup can prohibit airflow, lowering the evaporator’s skill to vaporize the refrigerant.

- Liquid refrigerant getting into the compressor (slugging): It is a significant issue requiring quick consideration.

-

Excessive Superheat: If the superheat is simply too excessive (above the beneficial vary), it suggests potential issues similar to:

- Extreme refrigerant cost: The system might need an excessive amount of refrigerant, lowering effectivity.

- Restricted airflow over the evaporator coil: Much like low superheat, restricted airflow can result in excessive superheat.

- Defective enlargement valve or metering machine: A malfunctioning enlargement valve is probably not metering the refrigerant accurately.

- Excessive ambient temperature: Extraordinarily excessive ambient temperatures can result in increased superheat.

Elements Affecting Superheat Readings:

A number of components can affect superheat readings, and it is essential to contemplate them for correct prognosis:

- Ambient Temperature: Larger ambient temperatures can improve superheat.

- Evaporator Coil Situation: A grimy or iced-up evaporator coil will have an effect on superheat readings.

- Refrigerant Cost: The quantity of refrigerant considerably impacts superheat.

- Airflow over the Evaporator Coil: Restricted airflow results in increased superheat.

- Accuracy of Measuring Devices: Utilizing correctly calibrated gauges and thermometers is crucial for correct readings.

Conclusion:

The R-410A superheat chart is an indispensable instrument for HVAC technicians. Understanding methods to interpret and make the most of this chart permits for environment friendly troubleshooting, improved system efficiency, and the prevention of pricey repairs. By precisely measuring stress and temperature and accurately deciphering the info from the chart, technicians can guarantee optimum system operation and lengthen the lifespan of HVAC tools. Keep in mind, at all times seek the advice of the producer’s specs for beneficial superheat ranges and comply with security procedures when working with refrigerants. Common system upkeep and cautious monitoring of superheat are key to making sure environment friendly and dependable cooling efficiency.

Closure

Thus, we hope this text has offered worthwhile insights into Decoding the R-410A Superheat Chart: A Complete Information for HVAC Technicians. We hope you discover this text informative and helpful. See you in our subsequent article!