Decoding The Schedule 40 Metal Pipe Weight Chart: A Complete Information

Decoding the Schedule 40 Metal Pipe Weight Chart: A Complete Information

Associated Articles: Decoding the Schedule 40 Metal Pipe Weight Chart: A Complete Information

Introduction

With nice pleasure, we’ll discover the intriguing subject associated to Decoding the Schedule 40 Metal Pipe Weight Chart: A Complete Information. Let’s weave fascinating data and supply contemporary views to the readers.

Desk of Content material

Decoding the Schedule 40 Metal Pipe Weight Chart: A Complete Information

Schedule 40 metal pipe is a ubiquitous materials in varied industries, from building and plumbing to grease and fuel. Understanding its weight is essential for correct materials estimations, structural calculations, and value projections. This complete information delves into the intricacies of Schedule 40 metal pipe weight charts, explaining their building, purposes, and find out how to successfully make the most of them.

What’s Schedule 40 Metal Pipe?

Schedule 40 is a designation that refers back to the pipe’s wall thickness. It isn’t a direct measurement of thickness however moderately a standardized system primarily based on the pipe’s nominal diameter and stress score. Schedule 40 pipes are identified for his or her comparatively thick partitions, offering superior power and stress resistance in comparison with lighter schedules like Schedule 10 or Schedule 20. This makes them appropriate for purposes demanding greater stress and sturdiness. The "metal" designation signifies that the pipe is produced from carbon metal, a powerful and versatile materials.

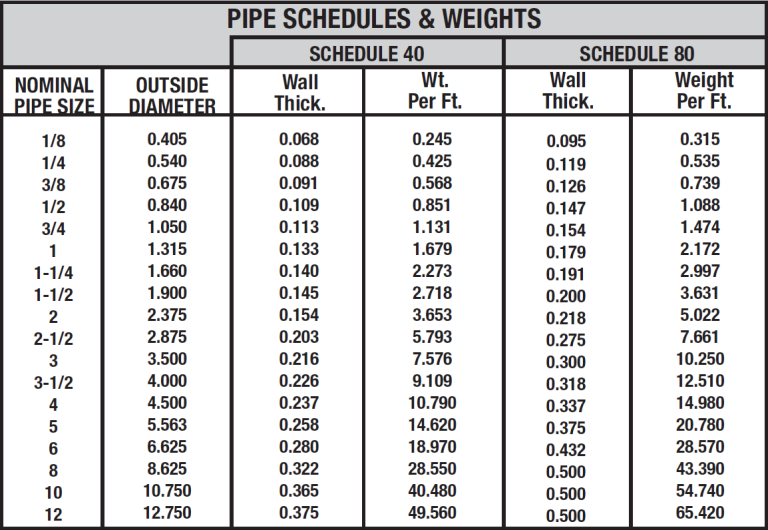

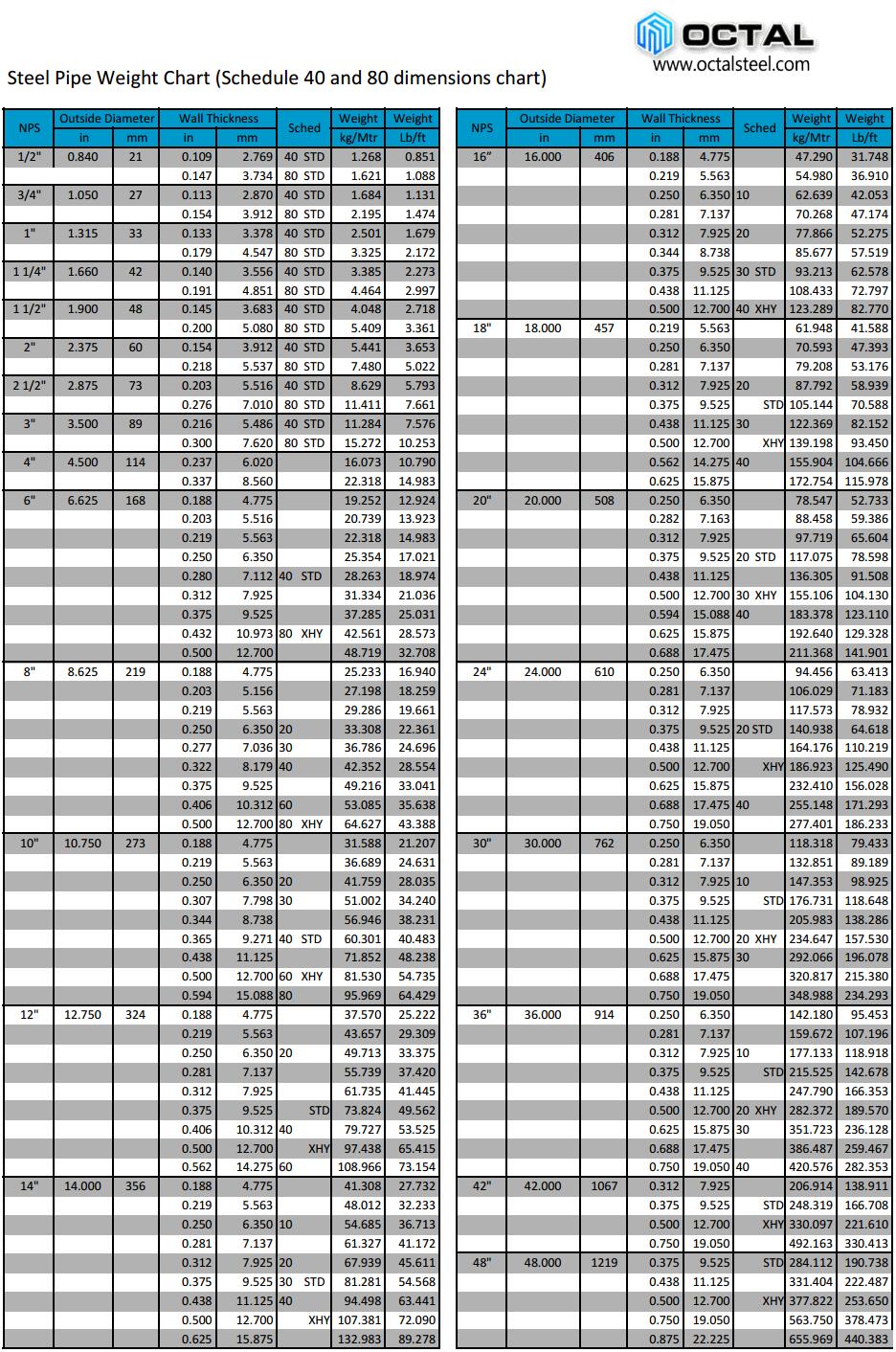

The Construction of a Schedule 40 Metal Pipe Weight Chart

A Schedule 40 metal pipe weight chart usually presents knowledge in a tabular format. The first columns often embody:

- Nominal Pipe Dimension (NPS): This isn’t the precise exterior diameter (OD) however a nominal measurement used for identification and standardization. For instance, a 1-inch NPS pipe does not essentially have a 1-inch OD.

- Exterior Diameter (OD): That is the precise measured diameter of the pipe’s outer floor. The OD stays comparatively constant throughout totally different schedules for a given NPS.

- Wall Thickness (WT): That is the thickness of the pipe’s wall. That is the place the "Schedule 40" designation comes into play, defining a selected wall thickness for every NPS.

- Inside Diameter (ID): That is the diameter of the pipe’s internal bore. It is calculated by subtracting twice the wall thickness from the skin diameter.

- Weight per Foot (W/ft): That is the burden of a one-foot size of the pipe, often expressed in kilos (lbs) or kilograms (kg). That is the essential knowledge level for materials estimation.

Elements Affecting Schedule 40 Metal Pipe Weight

A number of elements affect the burden of Schedule 40 metal pipe, even inside the identical NPS:

- Materials Grade: Completely different grades of carbon metal have barely various densities, resulting in minor weight variations. Whereas the variation is often small, it may be important in large-scale initiatives.

- Manufacturing Tolerances: Manufacturing processes introduce slight variations in dimensions, which consequently have an effect on the burden. These tolerances are often inside acceptable limits outlined by trade requirements.

- Pipe Size: The load is immediately proportional to the size. An extended pipe will naturally weigh extra. Charts usually present the burden per foot, permitting for simple calculation of the entire weight for any given size.

- Floor End: Whereas usually negligible, coatings or floor remedies can add a small quantity of weight.

The best way to Use a Schedule 40 Metal Pipe Weight Chart

Utilizing a Schedule 40 metal pipe weight chart is easy:

- Decide the required NPS: Establish the nominal pipe measurement wanted on your utility primarily based on move price, stress necessities, and different design concerns.

- Find the NPS within the chart: Discover the row similar to your chosen NPS.

- Discover the Weight per Foot: The load per foot (W/ft) is often listed in the identical row because the NPS.

- Calculate the entire weight: Multiply the burden per foot by the entire size of pipe required on your mission.

Instance:

For example you want 100 toes of 2-inch Schedule 40 metal pipe. A typical chart would possibly present a 2-inch NPS pipe has a weight per foot of roughly 5.77 lbs. Subsequently, the entire weight can be 100 toes * 5.77 lbs/foot = 577 lbs.

Functions of Schedule 40 Metal Pipe

Schedule 40 metal pipes are used extensively in varied purposes resulting from their power and sturdiness:

- Water Distribution Programs: Their stress resistance makes them splendid for transporting water over lengthy distances.

- Pure Gasoline Pipelines: They’re generally utilized in pure fuel distribution networks.

- Industrial Processes: Many industrial processes make the most of Schedule 40 pipes for conveying fluids, gases, and slurries.

- Development: They’re utilized in structural purposes, akin to scaffolding and help constructions.

- Plumbing Programs: In business and industrial settings, they’re used for high-pressure plumbing methods.

- Oil and Gasoline Refineries: Schedule 40 pipes play a crucial function within the advanced piping methods of refineries.

Significance of Correct Weight Calculation

Correct weight calculation is paramount for a number of causes:

- Materials Procurement: Exact weight estimations make sure you order the right amount of fabric, avoiding waste or shortages.

- Transportation Prices: The load immediately impacts transportation prices, as heavier shipments require bigger autos and incur greater charges.

- Structural Design: In structural purposes, correct weight is essential for load calculations and making certain structural integrity.

- Price Estimation: Correct weight knowledge permits for exact price estimations, facilitating higher mission budgeting and administration.

Discovering and Using On-line Sources

Quite a few on-line sources present Schedule 40 metal pipe weight charts. These charts typically embody further data, akin to dimensions and materials specs. All the time make sure the supply is respected and the chart aligns with related trade requirements. Many pipe producers and distributors supply downloadable charts on their web sites. On-line calculators are additionally accessible that simplify the burden calculation course of, eliminating the necessity for handbook calculations.

Conclusion

The Schedule 40 metal pipe weight chart is an important instrument for anybody working with this frequent materials. Understanding its construction, the elements influencing weight, and find out how to successfully make the most of the chart is essential for environment friendly mission planning, correct materials ordering, and cost-effective implementation. By leveraging available sources and using cautious calculations, professionals can guarantee their initiatives are profitable and compliant with trade requirements. Keep in mind to at all times confirm the burden knowledge with the precise producer’s specs to account for variations in materials grade and manufacturing tolerances. Correct weight calculation isn’t just a element; it is a cornerstone of profitable mission execution.

Closure

Thus, we hope this text has offered invaluable insights into Decoding the Schedule 40 Metal Pipe Weight Chart: A Complete Information. We admire your consideration to our article. See you in our subsequent article!