Decoding The TMT Bar Weight Chart: A Complete Information For Development Professionals

Decoding the TMT Bar Weight Chart: A Complete Information for Development Professionals

Associated Articles: Decoding the TMT Bar Weight Chart: A Complete Information for Development Professionals

Introduction

With nice pleasure, we are going to discover the intriguing subject associated to Decoding the TMT Bar Weight Chart: A Complete Information for Development Professionals. Let’s weave fascinating info and supply recent views to the readers.

Desk of Content material

Decoding the TMT Bar Weight Chart: A Complete Information for Development Professionals

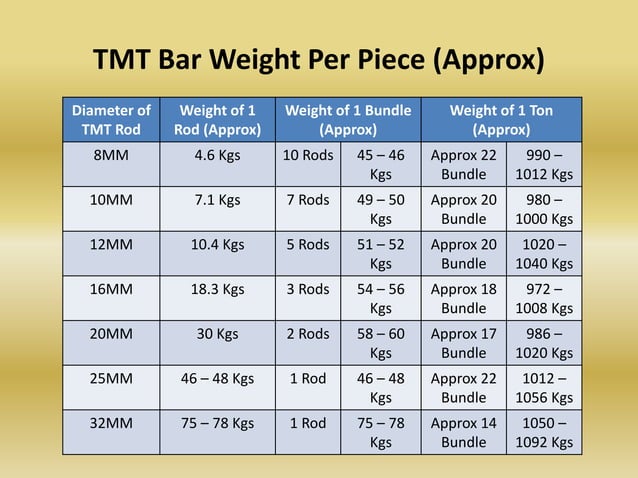

Reinforcement bars, generally generally known as rebars or TMT bars (Thermo-Mechanically Handled bars), are the spine of any bolstered concrete construction. Their power and integrity are paramount to the security and longevity of buildings, bridges, and different constructions. Understanding the load of those bars is essential for correct materials estimation, value calculation, and environment friendly challenge administration. This text offers a complete information to TMT bar weight charts, explaining their significance, interpret them, elements affecting weight, and customary misconceptions.

Understanding the Significance of TMT Bar Weight Charts

A TMT bar weight chart is a tabular illustration that correlates the diameter (or dimension) of a TMT bar with its weight per unit size (usually in kilograms per meter or kilos per foot). This seemingly easy chart is an important software for numerous stakeholders within the development business, together with:

- Engineers: Correct weight calculations are important for structural design. The chart ensures the correct quantity of metal is specified, contributing to structural integrity and avoiding over- or under-estimation.

- Contractors: Figuring out the load helps in correct materials ordering and value estimation. This prevents delays and monetary overruns resulting from inaccurate amount calculations.

- Suppliers: Suppliers use the chart to find out the load of the bars they provide, guaranteeing correct invoicing and stock administration.

- Inspectors: Weight verification is a vital side of high quality management. The chart offers a benchmark towards which the precise weight of delivered bars will be in contrast.

Deciphering the TMT Bar Weight Chart: A Step-by-Step Information

A typical TMT bar weight chart is organized with columns representing the bar diameter (often in millimeters) and rows indicating the corresponding weight per unit size. As an example, a chart may present that an 8mm diameter TMT bar weighs roughly 0.616 kg/meter.

Here is a breakdown of interpret the chart successfully:

-

Establish the required diameter: Decide the diameter of the TMT bar specified within the structural design drawings. That is often indicated in millimeters (mm).

-

Find the diameter within the chart: Discover the corresponding diameter column within the TMT bar weight chart.

-

Discover the load per unit size: Find the load worth akin to the chosen diameter. This worth often represents the load per meter (kg/m) or per foot (lbs/ft).

-

Calculate the overall weight: Multiply the load per unit size by the overall size of the TMT bar required for the challenge. It will give the overall weight of the TMT bars wanted.

Elements Affecting TMT Bar Weight

Whereas the diameter is the first determinant of a TMT bar’s weight, a number of different elements can subtly affect the ultimate weight:

- Manufacturing tolerances: Slight variations within the manufacturing course of can result in minor deviations from the theoretical weight indicated within the chart. These variations are usually inside acceptable limits specified by related requirements.

- Materials composition: The precise chemical composition of the metal utilized in manufacturing can affect the density and thus the load. Whereas minimal, these variations exist between completely different metal grades and producers.

- Floor end: The floor end of the TMT bar can barely have an effect on the general weight. Nevertheless, this impact is often negligible in comparison with the affect of diameter.

- Measurement accuracy: The accuracy of the measuring devices used to find out the bar’s size and diameter will influence the precision of the load calculation.

Widespread Misconceptions about TMT Bar Weight Charts

A number of misconceptions encompass using TMT bar weight charts:

- One-size-fits-all chart: There is not a single common TMT bar weight chart. Totally different producers could have barely various charts resulting from variations in manufacturing processes and metal grades. All the time check with the chart offered by the precise provider.

- Ignoring tolerances: It is essential to know that the weights indicated within the chart are theoretical values. Slight variations are anticipated resulting from manufacturing tolerances. Overly strict adherence to the chart with out contemplating these tolerances can result in pointless disputes.

- Neglecting the unit of measurement: All the time pay shut consideration to the unit of measurement (kg/m or lbs/ft) used within the chart to keep away from calculation errors.

- Assuming fixed weight per unit size: Whereas the load per unit size is basically decided by the diameter, elements like manufacturing tolerances can result in slight variations. It is best to test the load of a pattern batch to make sure consistency.

Significance of Correct Weight Calculation in Development Initiatives

Correct TMT bar weight calculation isn’t merely a technical element; it is a vital side of profitable challenge execution. Inaccurate estimations can result in a number of issues:

- Value overruns: Underestimating the required amount of TMT bars results in further prices through the challenge’s execution.

- Mission delays: Inadequate materials availability resulting from inaccurate estimations could cause important delays.

- Structural compromises: Utilizing an inadequate quantity of metal can compromise the structural integrity of the constructing, probably resulting in security hazards.

- Waste administration points: Overestimating the amount results in extra materials, rising waste disposal prices and environmental influence.

Conclusion:

The TMT bar weight chart is an indispensable software for all stakeholders within the development business. Understanding its significance, interpret it accurately, and the elements that may affect weight are essential for correct materials estimation, value administration, and guaranteeing the structural integrity and security of development initiatives. All the time check with the producer’s specified chart, account for manufacturing tolerances, and double-check calculations to keep away from expensive errors and potential security hazards. By using the TMT bar weight chart successfully, development professionals can contribute to extra environment friendly, cost-effective, and structurally sound initiatives. The precision and accuracy provided by these charts are basic to the success of any development endeavor.

Closure

Thus, we hope this text has offered priceless insights into Decoding the TMT Bar Weight Chart: A Complete Information for Development Professionals. We admire your consideration to our article. See you in our subsequent article!