Decoding The Wire Gauge: A Complete Information For Jewellery Makers

Decoding the Wire Gauge: A Complete Information for Jewellery Makers

Associated Articles: Decoding the Wire Gauge: A Complete Information for Jewellery Makers

Introduction

With nice pleasure, we’ll discover the intriguing matter associated to Decoding the Wire Gauge: A Complete Information for Jewellery Makers. Let’s weave fascinating info and provide contemporary views to the readers.

Desk of Content material

Decoding the Wire Gauge: A Complete Information for Jewellery Makers

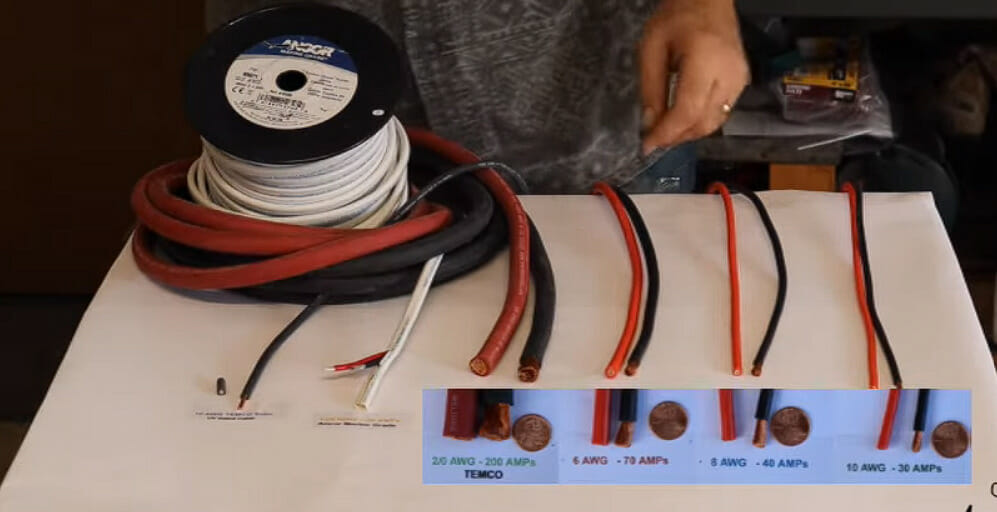

Choosing the proper wire gauge is essential for any jewellery maker. Whether or not you are crafting delicate earrings or sturdy bracelets, the diameter of your wire immediately impacts the power, sturdiness, and general aesthetic of your piece. Understanding wire gauge will be initially complicated, because the system works inversely – smaller gauge numbers point out thicker wires. This text delves into the intricacies of wire gauge sizes for jewellery making, offering an in depth chart, explanations of various gauges, and steerage on choosing the suitable gauge for varied tasks.

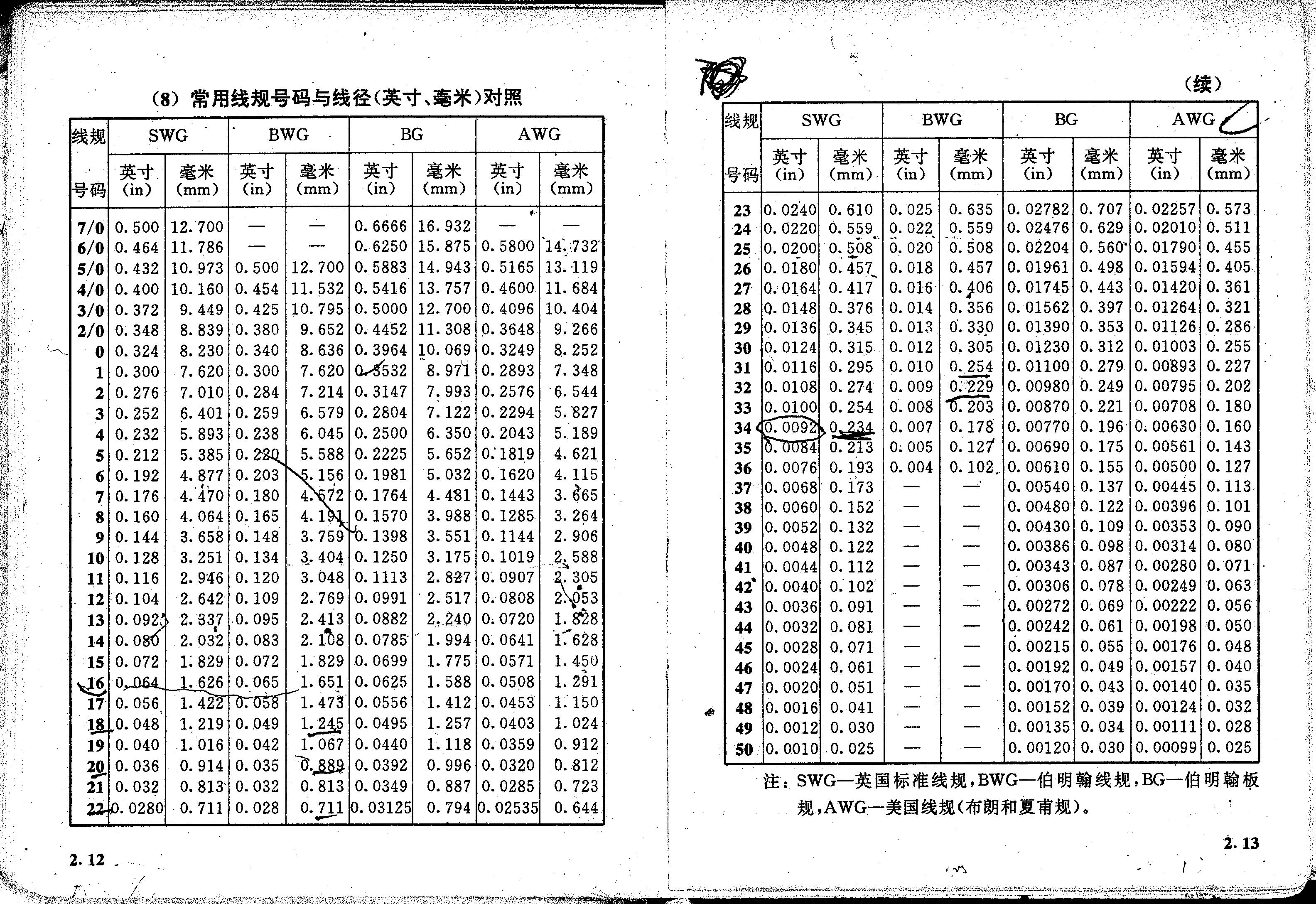

Understanding the American Wire Gauge (AWG) System

The most typical system used to measure wire diameter is the American Wire Gauge (AWG), also called the Brown & Sharpe (B&S) wire gauge. This method is logarithmic, that means every gauge quantity represents a constant proportional enhance or lower in diameter. Particularly, a distinction of three gauge numbers corresponds to a doubling or halving of the wire’s cross-sectional space. Which means a 20-gauge wire has roughly twice the cross-sectional space of a 23-gauge wire. This logarithmic scale makes it simpler to visualise the relative variations between gauges, although the precise diameter modifications aren’t linear.

It is essential to recollect the inverse relationship: smaller gauge quantity = thicker wire; bigger gauge quantity = thinner wire. This typically journeys up freshmen, so hold this key truth in thoughts all through your wire-working journey.

Wire Gauge Dimension Chart for Jewellery Making:

The next chart offers a complete overview of generally used wire gauges in jewellery making, together with their approximate diameters and instructed functions. Do not forget that these are approximations, and slight variations can happen between producers. All the time double-check the specs offered by your wire provider.

| AWG | Diameter (inches) | Diameter (mm) | Approximate Diameter (mm) | Advised Functions |

|---|---|---|---|---|

| 20 | 0.03196 | 0.812 | 0.8 | Sturdy earrings, bracelets, pendants, wrapping bigger stones |

| 22 | 0.02535 | 0.644 | 0.65 | Earrings, pendants, smaller bracelets, beading wire |

| 24 | 0.02010 | 0.511 | 0.5 | Delicate earrings, pendants, beading, wire wrapping smaller stones |

| 26 | 0.01594 | 0.405 | 0.4 | Very delicate earrings, pendants, intricate beadwork, high quality wire wrapping |

| 28 | 0.01264 | 0.321 | 0.32 | Extraordinarily high quality jewellery, intricate wirework, delicate findings |

| 30 | 0.01003 | 0.255 | 0.25 | Microsculpture, extraordinarily high quality jewellery particulars, bead embroidery |

| 32 | 0.00795 | 0.202 | 0.2 | Intricate particulars, very high quality wire weaving |

| 34 | 0.00630 | 0.160 | 0.16 | Superior wirework, extraordinarily delicate items |

| 36 | 0.00500 | 0.127 | 0.13 | Extraordinarily high quality particulars, specialised functions |

Be aware: The "Approximate Diameter (mm)" column offers a simplified, easier-to-remember worth. All the time discuss with the exact diameter in inches or millimeters offered by your provider for correct calculations and constant outcomes.

Selecting the Proper Gauge for Your Venture:

The choice of the suitable wire gauge relies upon closely on the precise undertaking and desired end result. Take into account these elements:

-

Weight and Sturdiness: Heavier gauge wires (smaller numbers) are stronger and extra sturdy, appropriate for items that can endure each day put on and tear, comparable to rings and bracelets. Lighter gauge wires (bigger numbers) are perfect for delicate gadgets comparable to earrings and pendants, the place much less weight and a finer look are prioritized.

-

Stone Dimension and Setting: When wire-wrapping stones, the gauge ought to be chosen primarily based on the dimensions and weight of the stone. Bigger, heavier stones require thicker wire to supply satisfactory assist and stop breakage.

-

Design Intricacy: Intricate designs requiring many bends and twists typically profit from barely thicker wire to forestall breakage throughout manipulation. Very high quality particulars, nonetheless, could necessitate using thinner gauge wires for precision and finesse.

-

Metallic Sort: The metallic itself influences the selection of gauge. Softer metals like silver and copper could require a barely thicker gauge than tougher metals like metal or brass to take care of structural integrity.

-

Meant Use: Take into account the supposed use of the jewellery. A bit meant for on a regular basis put on ought to be made with a extra sturdy, heavier gauge wire in comparison with a fragile piece for a special day.

Examples of Wire Gauge Utilization:

- Heavy-duty bracelets: 18-20 gauge

- Sturdy earrings: 20-22 gauge

- Delicate earrings: 24-26 gauge

- Pendants: 22-26 gauge, relying on measurement and complexity

- Wire wrapping stones: Gauge will depend on stone measurement; usually 20-26 gauge

- Beading wire: 22-26 gauge, relying on bead measurement and design

- Wire weaving: 26-32 gauge, relying on the intricacy of the sample

- Microsculpture: 30-36 gauge

Working with Totally different Wire Gauges:

Working with completely different wire gauges requires completely different strategies and instruments. Thicker wires require extra drive for bending and shaping, and might have stronger pliers. Thinner wires are extra delicate and liable to breakage, requiring gentler dealing with and doubtlessly finer instruments.

Past AWG: Different Wire Gauge Techniques

Whereas AWG is the commonest system in america, different methods exist, together with the Customary Wire Gauge (SWG) and the Birmingham Wire Gauge (BWG). These methods use completely different numbering schemes and will not be immediately akin to AWG. All the time test the producer’s specs to make sure you’re utilizing the proper gauge to your undertaking.

Conclusion:

Understanding wire gauge is key to profitable jewellery making. By rigorously contemplating the elements outlined on this article and using the offered chart as a reference, you possibly can confidently choose the suitable wire gauge to your tasks, guaranteeing the creation of gorgeous, sturdy, and aesthetically pleasing jewellery. Keep in mind to at all times prioritize security when working with wire, utilizing acceptable instruments and strategies to keep away from damage. Experimentation and follow will refine your expertise and can help you grasp the artwork of selecting the proper wire gauge for every distinctive creation. With time and expertise, you may develop an intuitive sense of which gauges are finest fitted to completely different functions, enhancing your jewelry-making capabilities. Glad crafting!

Closure

Thus, we hope this text has offered useful insights into Decoding the Wire Gauge: A Complete Information for Jewellery Makers. We thanks for taking the time to learn this text. See you in our subsequent article!