Decoding The X-bar And S Charts: A Complete Information To Course of Management

Decoding the X-bar and S Charts: A Complete Information to Course of Management

Associated Articles: Decoding the X-bar and S Charts: A Complete Information to Course of Management

Introduction

With enthusiasm, let’s navigate by way of the intriguing subject associated to Decoding the X-bar and S Charts: A Complete Information to Course of Management. Let’s weave fascinating data and supply recent views to the readers.

Desk of Content material

Decoding the X-bar and S Charts: A Complete Information to Course of Management

Statistical Course of Management (SPC) is a strong device for monitoring and enhancing manufacturing and enterprise processes. On the coronary heart of many SPC purposes lie the X-bar and S charts, a paired management chart system designed to watch the central tendency (common) and variability (normal deviation) of a course of over time. Understanding the formulation behind these charts is essential for efficient implementation and interpretation. This text delves deep into the X-bar and S chart formulation, explaining their derivation, utility, and limitations.

Understanding the Fundamentals: X-bar and S Chart Rules

Earlier than diving into the formulation, let’s set up the basic ideas. The X-bar chart tracks the typical (imply) of subgroups of knowledge collected from the method. The S chart, concurrently, screens the usual deviation (or vary, in less complicated purposes) of those similar subgroups. By plotting these values over time, we are able to visually establish developments and patterns that point out course of instability or shifts within the imply or variability.

The important thing to efficient X-bar and S chart utilization lies in correctly choosing subgroups. Subgroups must be homogenous – collected inside a short while body below comparable working situations. This minimizes the affect of exterior components on the info and permits for a extra correct illustration of the method’s inherent variability. The scale of the subgroups (sometimes denoted as ‘n’) can be vital; bigger subgroups present extra exact estimates of the method imply and normal deviation, however require extra knowledge assortment effort.

The X-bar Chart Components: Monitoring the Central Tendency

The X-bar chart system is comparatively easy. It calculates the typical of the averages of a number of subgroups. Let’s break it down:

-

X-bar (X̄): This represents the general common of all subgroup means. It is the central tendency of the method being monitored.

-

X̄ᵢ: This represents the typical of the i-th subgroup. Every subgroup has its personal common calculated by summing the person knowledge factors throughout the subgroup and dividing by the subgroup measurement (n).

-

okay: This represents the overall variety of subgroups collected.

The system for calculating the general common (X̄) is:

X̄ = (Σ X̄ᵢ) / okay

The place:

- Σ X̄ᵢ = The sum of the averages of all ‘okay’ subgroups.

This system is straightforward to implement. After accumulating knowledge and calculating the typical for every subgroup, you sum these averages and divide by the variety of subgroups. The ensuing X̄ is then plotted on the X-bar chart. Management limits are calculated based mostly on this general common and the method normal deviation (mentioned under).

The S Chart Components: Monitoring the Course of Variability

The S chart focuses on monitoring the method variability, represented by the usual deviation (S) of every subgroup. A secure course of reveals constant variability. Will increase or decreases in variability typically sign underlying issues that should be addressed.

The system for calculating the typical normal deviation (S̄) is:

S̄ = (Σ Sᵢ) / okay

The place:

- Sᵢ: The usual deviation of the i-th subgroup. That is calculated utilizing the usual system for pattern normal deviation:

Sᵢ = √[ Σ(xᵢⱼ – X̄ᵢ)² / (n – 1) ]

The place:

- xᵢⱼ: The j-th knowledge level within the i-th subgroup.

- X̄ᵢ: The common of the i-th subgroup.

- n: The scale of every subgroup.

- (n-1): That is the Bessel’s correction, used to supply an unbiased estimate of the inhabitants normal deviation.

The S chart plots the person subgroup normal deviations (Sᵢ) together with its management limits, that are calculated based mostly on the typical normal deviation (S̄) and management chart constants (mentioned later). The S chart helps establish shifts in course of variability, indicating potential issues like machine put on, inconsistent materials high quality, or modifications in operator method.

Management Limits for X-bar and S Charts

The management limits for each X-bar and S charts are essential for interpretation. They outline the vary inside which the method is taken into account to be in statistical management. Factors falling outdoors these limits counsel a possible out-of-control state of affairs, warranting investigation.

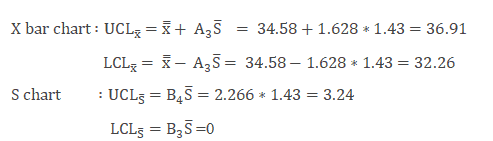

The management limits are calculated utilizing the next formulation:

For X-bar Chart:

- Higher Management Restrict (UCLₓ): X̄ + A₂S̄

- Heart Line (CLₓ): X̄

- Decrease Management Restrict (LCLₓ): X̄ – A₂S̄

For S Chart:

- Higher Management Restrict (UCLₛ): B₄S̄

- Heart Line (CLₛ): S̄

- Decrease Management Restrict (LCLₛ): B₃S̄

The place A₂, B₃, and B₄ are constants derived from management chart tables based mostly on the subgroup measurement (n). These constants account for the statistical properties of the pattern normal deviation and guarantee applicable management limits. These tables are available in statistical course of management textbooks and software program packages.

Selecting Between Vary (R) and Commonplace Deviation (S) Charts

Whereas the S chart makes use of the usual deviation, a less complicated various makes use of the vary (R) as a substitute. The vary is the distinction between the most important and smallest values in a subgroup. The R chart is simpler to calculate however much less environment friendly, significantly for bigger subgroups. The S chart supplies a extra exact estimate of variability, particularly with bigger subgroups. The selection is determined by the specified degree of precision and the computational assets accessible.

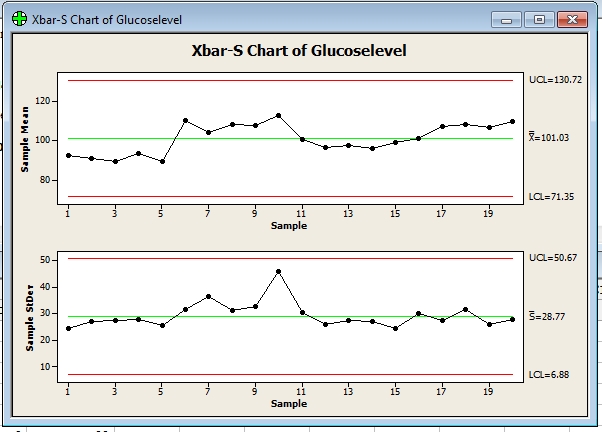

Decoding X-bar and S Charts

Decoding X-bar and S charts includes visually inspecting the plotted factors in opposition to the management limits. Factors outdoors the management limits sign potential course of instability. Patterns throughout the management limits, comparable to developments, cycles, or uncommon clustering, can even point out issues even when factors stay throughout the limits. These patterns typically level to assignable causes of variation that should be investigated and corrected.

Limitations of X-bar and S Charts

Whereas highly effective, X-bar and S charts have limitations:

- Assumption of Normality: The formulation assume that the info follows a traditional distribution. Important deviations from normality can have an effect on the accuracy of the management limits.

- Subgroup Choice: Improper subgroup choice can result in deceptive outcomes. Subgroups have to be consultant of the method and picked up below constant situations.

- Sensitivity to Small Shifts: Detecting small shifts within the course of imply or variability would possibly require a lot of subgroups.

- Lack of Info on Particular Causes: Whereas figuring out out-of-control conditions, the charts do not pinpoint the precise causes of variation. Additional investigation is important.

Conclusion:

The X-bar and S charts are elementary instruments in statistical course of management, offering a strong visible illustration of course of stability. Understanding the formulation behind these charts is essential for his or her efficient implementation and interpretation. By rigorously choosing subgroups, calculating management limits precisely, and deciphering the outcomes critically, practitioners can use X-bar and S charts to watch and enhance the effectivity and consistency of their processes. Keep in mind that these charts are best when used along side different problem-solving methods to establish and deal with the basis causes of course of variation. Utilizing statistical software program can simplify the calculations and enhance the accuracy of the evaluation. Nevertheless, an intensive understanding of the underlying ideas stays important for the profitable utility of those highly effective instruments.

Closure

Thus, we hope this text has supplied priceless insights into Decoding the X-bar and S Charts: A Complete Information to Course of Management. We thanks for taking the time to learn this text. See you in our subsequent article!