Understanding And Making use of The C-Chart: A Complete Information To Management Charting For Rely Information

Understanding and Making use of the C-Chart: A Complete Information to Management Charting for Rely Information

Associated Articles: Understanding and Making use of the C-Chart: A Complete Information to Management Charting for Rely Information

Introduction

On this auspicious event, we’re delighted to delve into the intriguing subject associated to Understanding and Making use of the C-Chart: A Complete Information to Management Charting for Rely Information. Let’s weave fascinating data and supply recent views to the readers.

Desk of Content material

Understanding and Making use of the C-Chart: A Complete Information to Management Charting for Rely Information

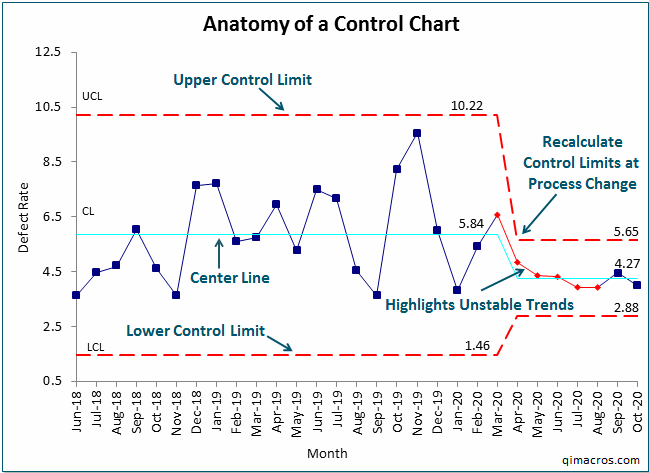

Management charts are indispensable instruments in statistical course of management (SPC), providing a visible illustration of course of stability and serving to determine sources of variation. Whereas many are aware of X-bar and R charts for steady information, understanding how one can monitor depend information requires a distinct strategy. That is the place the c-chart comes into play. This text offers a complete overview of the c-chart, explaining its objective, development, interpretation, and sensible functions.

What’s a C-Chart?

A c-chart is a kind of management chart used to observe the variety of defects or nonconformities present in a relentless pattern measurement. In contrast to p-charts, which monitor the proportion of defects, c-charts deal with the quantity of defects. The important thing distinction lies within the pattern measurement: p-charts use various pattern sizes, whereas c-charts assume a constant pattern measurement throughout all subgroups. This consistency is essential for the correct interpretation of the c-chart. The "c" in c-chart stands for "depend."

When to Use a C-Chart:

C-charts are significantly helpful in conditions the place:

- The pattern measurement is fixed: The variety of items inspected or the realm inspected stays the identical for every subgroup. This could possibly be the variety of gadgets produced in a batch, the variety of items in a cargo, or the realm of a floor inspected.

- The variety of defects is counted: The main focus is on counting the variety of defects, flaws, or nonconformities inside a relentless pattern measurement. Examples embody counting scratches on a painted floor, blemishes on a manufactured half, or errors in a doc.

- The defects should not associated: The incidence of 1 defect doesn’t affect the likelihood of one other defect occurring. This assumption of independence is vital for the validity of the c-chart. If defects are inclined to cluster collectively, a distinct management chart methodology could also be extra applicable.

Setting up a C-Chart:

Constructing a c-chart includes a number of key steps:

-

Outline the Course of and Pattern Dimension: Clearly outline the method being monitored and decide the constant pattern measurement (n) for every subgroup. This pattern measurement should stay fixed all through the information assortment interval.

-

Accumulate Information: Accumulate information on the variety of defects (c) present in every subgroup. Guarantee constant information assortment strategies are used to reduce bias. A enough variety of subgroups (sometimes at the least 20-25) is really helpful for dependable evaluation.

-

Calculate the Common Variety of Defects: Calculate the common variety of defects (c-bar) throughout all subgroups. That is performed by summing the variety of defects in every subgroup and dividing by the entire variety of subgroups (ok):

c-bar = Σcᵢ / ok

the place:

- Σcᵢ is the sum of defects throughout all subgroups

- ok is the variety of subgroups

-

Calculate the Management Limits: The management limits are calculated utilizing the common variety of defects (c-bar). For a c-chart, the management limits are primarily based on the Poisson distribution, which is often used to mannequin depend information. The formulation for the higher management restrict (UCL) and decrease management restrict (LCL) are:

UCL = c-bar + 3√c-bar

LCL = c-bar – 3√c-barThe issue of three represents three commonplace deviations from the imply, offering roughly 99.7% confidence that factors falling throughout the limits characterize widespread trigger variation. Nonetheless, if the LCL is calculated as a unfavourable quantity, it is set to zero, as you can not have a unfavourable variety of defects.

-

Plot the Information: Plot the variety of defects (c) for every subgroup on the chart, together with the central line (c-bar) and the higher and decrease management limits (UCL and LCL).

-

Analyze the Chart: Look at the chart for any factors that fall outdoors the management limits or exhibit non-random patterns. Factors outdoors the management limits recommend particular trigger variation, whereas non-random patterns point out potential course of points.

Decoding a C-Chart:

The interpretation of a c-chart focuses on figuring out deviations from the anticipated course of conduct. The next conditions point out potential issues:

-

Factors outdoors the management limits: Factors falling above the UCL or under the LCL (if LCL > 0) point out particular trigger variation. This implies {that a} vital change has occurred within the course of, requiring investigation to determine and proper the basis trigger.

-

Non-random patterns: Even when all factors fall throughout the management limits, non-random patterns resembling developments, cycles, or stratification recommend underlying points. These patterns point out that the method will not be secure, though it would seem like inside management. Examples embody:

- Traits: A constant upward or downward motion of factors.

- Cycles: Recurring patterns of excessive and low defect counts.

- Stratification: Factors persistently clustering above or under the central line.

-

Runs: A run is a sequence of consecutive factors above or under the central line. Lengthy runs can point out a shift within the course of imply, even when no factors fall outdoors the management limits.

Sensible Functions of C-Charts:

C-charts discover widespread utility throughout varied industries:

-

Manufacturing: Monitoring the variety of defects in a batch of manufactured components, the variety of blemishes on a completed product, or the variety of errors in an meeting course of.

-

Healthcare: Monitoring the variety of infections in a hospital ward, the variety of remedy errors, or the variety of opposed occasions.

-

Service Industries: Monitoring the variety of buyer complaints, the variety of errors in a service course of, or the variety of defects in a doc evaluate course of.

-

Meals Business: Monitoring the variety of contaminants present in meals samples, the variety of defects in packaging, or the variety of situations of non-compliance with security rules.

-

Software program Growth: Monitoring the variety of bugs discovered throughout software program testing, the variety of defects in a code evaluate, or the variety of system crashes.

Limitations of C-Charts:

Whereas c-charts are highly effective instruments, it is essential to pay attention to their limitations:

-

Fixed Pattern Dimension: The requirement for a relentless pattern measurement may be restrictive in some conditions. If the pattern measurement varies, a u-chart (which accounts for various pattern sizes) needs to be used as a substitute.

-

Independence of Defects: The idea of impartial defects is essential. If defects are inclined to cluster, the c-chart could not precisely mirror the method variability.

-

Poisson Distribution Assumption: The c-chart depends on the Poisson distribution to mannequin the defect counts. If the information considerably deviates from a Poisson distribution, the management limits is probably not correct.

Conclusion:

The c-chart is a helpful instrument for monitoring the variety of defects in a course of with a relentless pattern measurement. By rigorously setting up and decoding the chart, organizations can determine sources of variation, enhance course of stability, and finally cut back defects. Nonetheless, it is essential to grasp the assumptions underlying the c-chart and to decide on the suitable management chart methodology primarily based on the particular traits of the information being monitored. Correct coaching and understanding are important for efficient utility and interpretation of c-charts to make sure correct course of monitoring and enchancment.

Closure

Thus, we hope this text has supplied helpful insights into Understanding and Making use of the C-Chart: A Complete Information to Management Charting for Rely Information. We admire your consideration to our article. See you in our subsequent article!